Top Ladle Castable Manufacturer Offers High-Quality Products

By:Admin

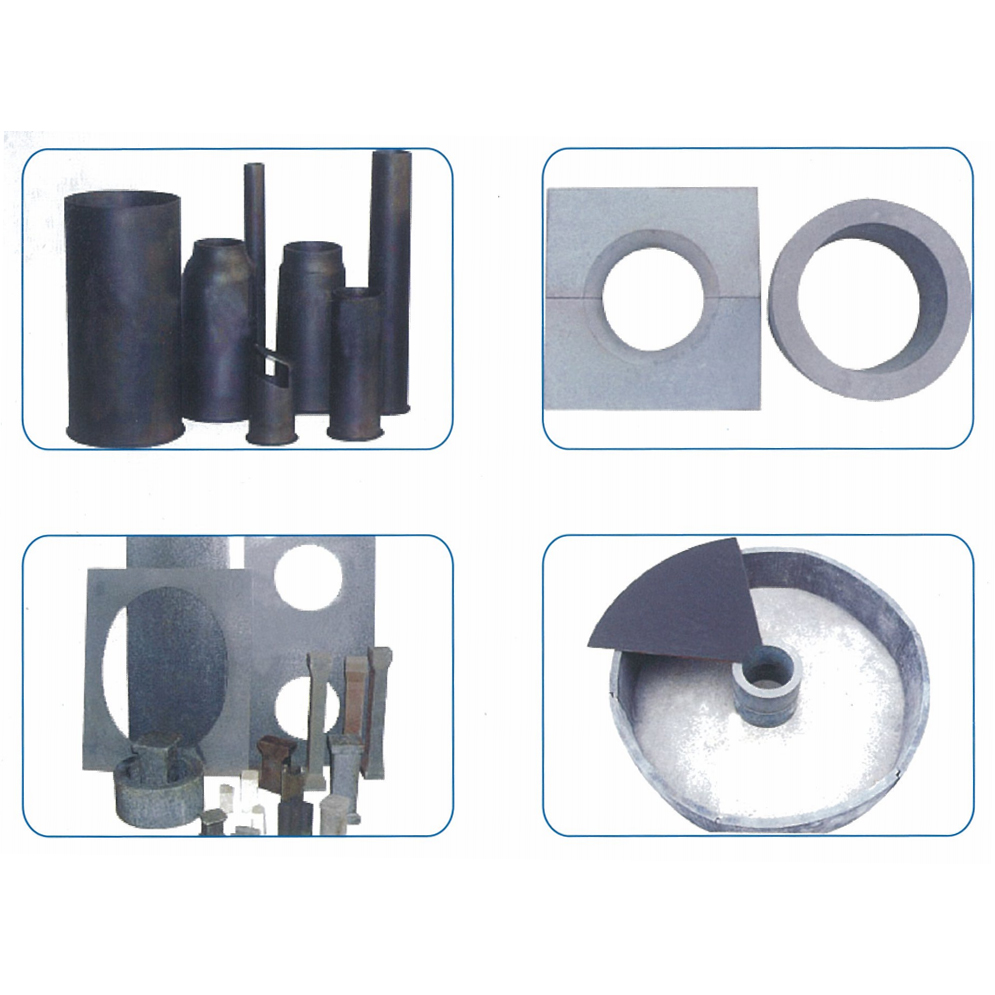

Ladle castables are an essential component in the steel industry, as they play a crucial role in maintaining the temperature and integrity of ladles used for the transport and pouring of molten steel. One company has been leading the way in providing innovative ladle castable solutions, pushing the boundaries of technology and setting new standards for the industry.

With a commitment to excellence and a focus on research and development, {Company name} has solidified its position as a trusted and reliable ladle castable manufacturer. The company's dedication to quality and innovation has allowed it to consistently deliver superior products that meet the specific needs and requirements of its customers.

{Company name} has been at the forefront of ladle castable manufacturing for over two decades, continually striving to improve its products and processes. The company's state-of-the-art production facilities and advanced testing equipment ensure that each ladle castable is of the highest quality and performance.

One of the key factors that set {Company name} apart from its competitors is its emphasis on research and development. The company has a team of experienced and skilled researchers and engineers who are constantly exploring new materials and technologies to enhance the performance of ladle castables. This commitment to innovation has enabled {Company name} to develop cutting-edge solutions that provide superior thermal insulation, erosion resistance, and overall durability.

In addition to its focus on research and development, {Company name} also places a strong emphasis on environmental sustainability. The company is dedicated to reducing its environmental impact by utilizing eco-friendly materials and minimizing waste in its production processes. By incorporating sustainable practices into its operations, {Company name} is not only meeting the needs of its customers but also contributing to a cleaner and greener future.

Furthermore, {Company name} has established a reputation for providing exceptional customer service and technical support. The company's team of experts works closely with clients to understand their specific requirements and offer tailored solutions to meet their needs. Whether it's providing technical recommendations, on-site support, or troubleshooting assistance, {Company name} goes above and beyond to ensure that its customers are satisfied with the performance of its ladle castables.

Beyond its commitment to excellence and innovation, {Company name} also places a strong emphasis on quality control. The company rigorously tests each batch of ladle castables to ensure that they meet the highest standards for strength, thermal shock resistance, and overall performance. This dedication to quality assurance has earned {Company name} the trust and loyalty of its customers, who rely on the company's products for their critical steel manufacturing processes.

Looking towards the future, {Company name} is poised to continue its leadership in the ladle castable industry. The company remains dedicated to pushing the boundaries of technology, enhancing its product offerings, and providing unparalleled service to its clients. With a focus on innovation, sustainability, and quality, {Company name} is well-positioned to meet the evolving needs of the steel industry and maintain its status as a leading ladle castable manufacturer.

In conclusion, {Company name} has set itself apart as a top ladle castable manufacturer through its unwavering commitment to excellence, innovation, and customer satisfaction. With a focus on research and development, environmental sustainability, and quality control, the company has established itself as a trusted partner for steel manufacturers around the world. As the industry continues to evolve, {Company name} is well-equipped to lead the way with its innovative solutions and dedication to superior performance.

Company News & Blog

Top Acid Proof Bricks: A Comprehensive Guide for Durable Construction

Acid Proof Brick - A Reliable Solution for Industrial CorrosionIn the fast-paced world of industrial manufacturing, corrosion remains a constant challenge. Factories rely on various chemicals and processes to produce goods, but these can also harm the very structures that house them. Addressing this issue, ACME Inc., a prominent manufacturer of construction materials, has introduced a groundbreaking solution known as Acid Proof Brick.Acid Proof Brick is a highly durable and chemical-resistant construction material that offers unmatched protection against corrosive substances. The bricks are crafted using a combination of high-quality clay, silica, and alumina, which undergo an intense firing process. This meticulous technique gives the bricks exceptional density, strength, and resistance to acids, bases, and alkalis.One of the key advantages of Acid Proof Brick is its ability to withstand extreme temperatures, making it suitable for a wide range of industries such as chemical plants, oil refineries, power stations, and metal processing facilities. The brick's resistance to thermal shocks ensures that it maintains its integrity even in the harshest environments, preventing potential accidents and prolonging the lifespan of the structures.Moreover, Acid Proof Brick offers exceptional dimensional stability. This means that it maintains its shape and size over time, minimizing the risk of cracks and leaks in the structures. This stability eliminates the need for regular maintenance and repairs, saving companies valuable time and resources in the long run.The installation process of Acid Proof Brick is also worth noting. ACME Inc. provides comprehensive guidance and support to ensure a seamless installation. With their team of highly skilled technicians, they assist clients in every step of the process, from preparation to final inspection. This commitment to customer satisfaction sets ACME Inc. apart from its competitors and has contributed to their impressive track record in providing reliable construction materials.In addition to its superior resistance to corrosion, Acid Proof Brick also offers easy cleaning and maintenance. Its smooth surface allows for effortless removal of chemical residue, ensuring a safe and hygienic working environment. This quality not only benefits the infrastructure but also plays a crucial role in meeting stringent industry regulations and standards.ACME Inc. has emerged as a reliable and trusted provider of Acid Proof Brick due to their commitment to innovation and quality. Their state-of-the-art manufacturing facilities, equipped with modern machinery and stringent quality control measures, ensure that every brick meets the highest standards. Furthermore, the company remains proactive in researching and developing new materials and technologies to address evolving industry needs.The success of Acid Proof Brick can be attributed to its versatility and ability to adapt to various construction requirements. ACME Inc. understands that every industry has unique demands, and thus they offer customization options to suit individual project specifications. This flexibility ensures that their clients can achieve optimal results and enhance the efficiency of their operations.In conclusion, Acid Proof Brick has revolutionized the construction industry by offering robust protection against corrosion and chemical damage. ACME Inc.'s commitment to quality, innovation, and customer satisfaction has made them a go-to choice for industries facing the challenges of extreme environments. With their reliable support and exceptional materials, companies can now focus on their core operations, confident in the durability and longevity of their infrastructure.

Insulation Refractory: What You Need to Know

Bonded Insulation Refractory (BIR) is a leading manufacturer of high-quality insulation and refractory products. With a dedication to quality and innovation, BIR has established itself as a trusted supplier in the industry.The company specializes in producing a wide range of insulation and refractory materials, including ceramic fiber products, insulating firebricks, and refractory castables. These products are used in various high-temperature applications, such as in the steel, aluminum, and petrochemical industries. BIR’s insulation and refractory materials are designed to withstand extreme temperatures and provide superior thermal insulation, making them essential for maintaining efficient and safe industrial operations.BIR takes pride in its state-of-the-art manufacturing facilities and cutting-edge technologies that allow the company to produce top-of-the-line products. The company’s dedicated team of engineers and technicians work tirelessly to develop innovative solutions and improve the performance of its insulation and refractory materials. BIR’s commitment to research and development has enabled it to stay at the forefront of the industry and consistently deliver products that meet the highest standards of quality and performance.In addition to its focus on product quality, BIR places a strong emphasis on environmental sustainability and safety. The company adheres to strict environmental regulations and strives to minimize its carbon footprint through efficient manufacturing processes and sustainable sourcing practices. BIR is also dedicated to ensuring the safety of its employees and customers, implementing rigorous safety protocols and conducting regular trainings to prevent workplace incidents.Furthermore, BIR has established a strong network of distribution partners and sales representatives, allowing the company to reach customers worldwide. With a global presence, BIR is able to provide its premium insulation and refractory products to a diverse range of industries and applications. The company’s dedication to customer satisfaction and its ability to offer tailored solutions have earned it a strong reputation among its clients.BIR’s success is built on a foundation of integrity, excellence, and reliability. The company is committed to upholding the highest standards of business ethics and professionalism in all of its operations. Its transparent and ethical business practices have earned the trust and loyalty of its customers, further solidifying BIR’s position as a leading supplier in the insulation and refractory industry.Looking to the future, BIR remains focused on continuous improvement and innovation. The company is dedicated to further advancing its technologies and expanding its product offerings to meet the evolving needs of its customers. With a steadfast commitment to excellence, BIR is poised to continue leading the way in the insulation and refractory industry.In conclusion, Bonded Insulation Refractory (BIR) stands as a testament to quality, innovation, and excellence in the insulation and refractory industry. With a dedication to delivering top-of-the-line products, a commitment to environmental sustainability and safety, and a focus on customer satisfaction, BIR has firmly established itself as a trusted and reputable supplier. As the company looks to the future, its unwavering dedication to improvement and innovation ensures that BIR will continue to be a driving force in the industry for years to come.

High-Quality Ceramic Fiber Fire Blanket Roll for Effective Fire Protection

Ceramic Fiber Fire Blanket Roll - A Revolutionary Product Ensuring SafetyIn recent years, the demand for high-quality fire safety products has been rising rapidly, especially in industries where there is a high risk of fire accidents. Ceramic fiber fire blanket roll has emerged as a revolutionary product that not only provides excellent fire protection but also offers many other benefits. {Company Name} is a leading manufacturer of ceramic fiber fire blanket roll, which has gained a strong reputation for providing innovative solutions for fire safety. The company has been at the forefront of developing advanced materials that meet the highest industry standards and regulations.The ceramic fiber fire blanket roll is made from high-quality ceramic fibers that offer exceptional thermal insulation properties. This makes it an ideal choice for environments where there is a risk of high-temperature fires. The blanket roll is designed to withstand extreme heat and can provide effective protection for people and property in the event of a fire.One of the key advantages of the ceramic fiber fire blanket roll is its flexibility and ease of use. Unlike traditional fire safety products, the blanket roll can be easily rolled out and cut to fit any size or shape, making it highly versatile and adaptable to various applications. In addition, the blanket roll is lightweight and easy to handle, which makes it convenient for both installation and maintenance.With its excellent fire-resistant properties, the ceramic fiber fire blanket roll offers reliable protection against flames and heat, as well as protection from smoke and toxic gases. This makes it an essential safety measure for industries such as oil and gas, petrochemical, and manufacturing, where fires can have devastating consequences.{Company Name} takes great pride in its commitment to quality and safety. The company's ceramic fiber fire blanket roll is tested and certified to meet the most rigorous international standards, ensuring that it provides the highest level of protection in the event of a fire. Furthermore, the company's team of experts is dedicated to providing exceptional customer service and technical support, ensuring that clients have the knowledge and resources they need to use the product effectively.In addition to its excellent fire protection properties, the ceramic fiber fire blanket roll is also environmentally friendly. It is made from sustainable materials and does not release harmful chemicals or gases when exposed to heat. This not only makes it a safe choice for people and property but also demonstrates {Company Name}'s commitment to sustainability and eco-friendly practices.As the demand for high-quality fire safety products continues to grow, {Company Name} remains at the forefront of innovation in the industry. The company's ceramic fiber fire blanket roll is a reflection of its dedication to providing reliable and effective solutions for fire protection, ensuring the safety of people and property in a wide range of environments.In conclusion, the ceramic fiber fire blanket roll offered by {Company Name} is a testament to the company's commitment to excellence in fire safety. With its exceptional fire-resistant properties, flexibility, and environmental sustainability, the blanket roll provides reliable protection in the event of a fire. As the demand for advanced fire safety products continues to rise, {Company Name} remains a trusted leader in the industry, providing innovative solutions that ensure the safety and well-being of its clients.

What is a Carbon Paste Electrode and its Functions in Electroanalytical Chemistry?

Carbon Paste Electrode: A Breakthrough in Electrochemical AnalysisIn today's rapidly advancing world, the need for accurate and efficient analytical methods has become paramount. Whether it is in the field of medicine, environmental sciences, or even industrial processes, the ability to detect and quantify various substances has never been more crucial. Recognizing this need, scientists at {} have introduced a revolutionary product – the Carbon Paste Electrode, a cutting-edge tool that promises to revolutionize the field of electrochemical analysis.Electrochemical analysis involves the measurement and interpretation of electrical properties associated with chemical reactions. Traditionally, electrodes made from metals like platinum or gold have been utilized in this process. However, such electrodes often suffer from limitations such as high cost, limited availability, and a propensity for surface contamination. In recent years, carbon-based electrodes have emerged as a popular alternative due to their affordability, versatility, and improved chemical stability.The Carbon Paste Electrode developed by {} takes the advantages of carbon-based electrodes to a whole new level. Composed of a mixture of carbonaceous material and a binding agent, this innovative electrode offers unparalleled performance and superior accuracy in electrochemical analysis. Its unique composition enables precise detection and quantification of a wide range of substances, including heavy metals, organic compounds, and various analytes of interest in environmental and pharmaceutical industries.One of the key advantages of the Carbon Paste Electrode lies in its exceptional durability. Traditional electrodes often suffer from frequent wear and tear, leading to inconsistent results and increased costs. However, with its high mechanical strength, the Carbon Paste Electrode is capable of enduring numerous repetitive analyses without compromising accuracy or reliability. This longevity not only improves cost-efficiency but also ensures consistent analytical outcomes, making it an indispensable tool for researchers and scientists.Furthermore, the Carbon Paste Electrode exhibits remarkable sensitivity, thus enabling the detection of trace amounts of analytes. Its highly porous structure allows for greater surface area, facilitating enhanced mass transport and promoting rapid electron transfer, ultimately leading to improved sensitivity and detection limits. As a result, the electrode can detect even the most minute quantities of substances, providing invaluable information for crucial applications such as environmental monitoring and pharmaceutical research.In addition to its superior performance, the Carbon Paste Electrode also boasts exceptional versatility. With the ability to be easily modified with various surface modifiers and nanoparticles, this electrode can be tailored to specific analytes, making it an incredibly adaptable tool for different analytical needs. Moreover, its compatibility with different electrolytes and solvents further enhances its versatility, allowing for efficient electrochemical analysis across a wide range of sample matrices.As research and development continue to drive advancements in various industries, the demand for reliable analytical tools has never been greater. Recognizing this need, {} has delivered a game-changing solution in the form of the Carbon Paste Electrode. Its exceptional performance, durability, sensitivity, and versatility make it a top choice for scientists and researchers worldwide.With this groundbreaking invention, the field of electrochemical analysis is poised to take a significant leap forward. The superior capabilities of the Carbon Paste Electrode promise to revolutionize the way substances are detected and analyzed, paving the way for more accurate and efficient research in fields ranging from medicine to environmental sciences. As {} continues to innovate and redefine the boundaries of electrochemical analysis, the future looks bright for the scientific community as a whole.

High-Quality Corundum Bricks: The Best Refractories on the Market

The [Company] is proud to announce the launch of its new line of Refractories Corundum Bricks, offering customers a high-quality solution for their refractory needs. The company, known for its dedication to providing top-notch refractory products, is excited to add this new offering to its already impressive portfolio.Refractories Corundum Bricks are essential for industries such as steel, cement, and glass manufacturing, where high temperatures and harsh conditions are common. These bricks are made from high purity fused alumina and are known for their excellent thermal shock resistance, high mechanical strength, and resistance to slag and alkali-erosion.With the addition of the Refractories Corundum Bricks to its product line, [Company] is poised to become a key player in the refractory industry. The company's commitment to research and development has enabled it to create a product that meets the needs of its customers while maintaining the highest quality standards."We are thrilled to introduce our new line of Refractories Corundum Bricks to the market," said [Name], CEO of [Company]. "These bricks are the result of extensive research and testing, and we are confident that they will exceed the expectations of our customers. Our goal is to provide the best possible solutions for the most demanding refractory applications, and these bricks are a testament to that commitment."The Refractories Corundum Bricks are available in various shapes and sizes to suit the specific needs of different industries. Whether it's lining a furnace, a kiln, or any other high-temperature application, these bricks are designed to deliver outstanding performance and longevity.In addition to their superior technical properties, the Refractories Corundum Bricks also offer environmental benefits. Their high resistance to erosion and corrosion means they have a longer lifespan, reducing the need for frequent replacements and resulting in lower maintenance costs. This, in turn, contributes to a more sustainable and eco-friendly manufacturing process.[Company] understands the importance of providing not only top-notch products but also exceptional customer service. The company's team of experts is available to provide technical support and assistance to help customers select the right products for their specific needs. This commitment to customer satisfaction has been a cornerstone of [Company]'s success and has earned the company a solid reputation in the industry.As the demand for high-quality refractory products continues to grow, [Company] remains at the forefront of innovation. The introduction of the Refractories Corundum Bricks is just one example of the company's dedication to meeting the evolving needs of its customers."We see a great opportunity in the market for superior refractory products, and we are committed to being a trusted partner for our customers," added [Name]. "The launch of our Refractories Corundum Bricks is just the beginning of our efforts to expand our product offerings and solidify our position as a leader in the industry."In conclusion, the launch of the Refractories Corundum Bricks is a significant milestone for [Company] and a testament to its commitment to excellence. With this new product line, the company is well-positioned to meet the growing demand for high-quality refractory solutions and continue its legacy of innovation and customer satisfaction.

Discover the Importance of Cement Kiln Bricks in Efficient Construction

Title: Sustainable Solution for Cement Kiln Bricks Pioneered by Industry LeaderIntroduction:In recent years, the global cement industry has been striving to become more sustainable and energy-efficient. One critical area of focus is the development of eco-friendly and durable kiln bricks. Recognizing this need, a leading cement producer has successfully introduced a breakthrough product that promises to revolutionize the sector. The innovative cement kiln bricks, designed to remove the brand name, present a sustainable solution that aligns with the company's commitment to environmental stewardship.Company Overview:The global cement industry leader, with a robust presence in multiple regions, has always been at the forefront of positive change. Recognized for its commitment to sustainable practices, innovation, and social responsibility, the company continuously invests in research and development to bring advanced and eco-friendly solutions to the market.Eco-Friendly Cement Kiln Bricks:The newly developed cement kiln bricks offer unparalleled benefits, both in terms of sustainability and performance. Unlike traditional kiln bricks that are largely composed of clay and other non-renewable materials, these innovative bricks incorporate a significant proportion of recycled and sustainable materials, contributing to a circular economy.The incorporation of locally sourced alternative materials significantly reduces the carbon footprint associated with the bricks' manufacturing process. By utilizing recycled materials such as fly ash, slag, and industrial waste, these bricks demonstrate the company's commitment to reducing environmental impact without compromising on quality.Key Features and Advantages:1. Enhanced Energy Efficiency: By incorporating advanced insulating materials, the cement kiln bricks provide superior thermal insulation. This characteristic helps maximize energy efficiency within cement production facilities, ultimately reducing energy consumption and related costs.2. Longer Lifespan: The new bricks boast exceptional durability and resistance to high temperatures, considerably extending the lifespan of kilns. This increased longevity significantly reduces maintenance requirements and associated downtime, leading to minimal production disruptions.3. Decreased Emissions: The reduced firing temperature required for these kiln bricks contributes to a substantial decrease in greenhouse gas emissions. The company's commitment to lowering its carbon footprint aligns with global efforts to combat climate change.4. Improved Workplace Safety: The innovative bricks' unique composition allows for better heat retention, minimizing the external temperature of kilns. This improvement enhances worker safety by reducing accidental burns and injuries.Market Impact and Future Prospects:The introduction of these revolutionary cement kiln bricks is poised to have a significant impact on the global cement industry. The eco-friendly nature, superior performance, and cost-effectiveness of these bricks provide the company with a competitive edge. With an increasing emphasis on sustainability and environmental awareness, market demand for such solutions is expected to soar.Moreover, the pioneering efforts of this industry leader highlights the company's commitment to sustainable growth. By prioritizing eco-friendly technologies, the cement producer sets a benchmark for other companies to follow, driving an industry-wide shift towards greener practices.Conclusion:The global cement industry is undergoing a transformation towards sustainability, and the introduction of the innovative cement kiln bricks signifies a groundbreaking milestone. The eco-friendly nature, along with the superior performance and durability of these bricks, positions the company as a pioneer in the market.By prioritizing sustainable solutions, this industry leader not only reduces its environmental impact but also demonstrates its commitment to creating a greener future. With increasing market demand for eco-friendly technologies, the company is well-positioned to remain at the forefront of the global cement industry, setting an example for others to follow.

Durable Fireproof Bricks: A Must-Have for Your Building Needs

Fireproof Bricks Company Leads the Industry in Innovative Technology and Sustainable PracticesIn the realm of fire protection and construction materials, one company stands out for its commitment to innovation, quality, and sustainability – Fireproof Bricks Company. With a proud history of pioneering fireproof bricks and related products, Fireproof Bricks Company has solidified its position as a leader in the industry.Established in 1985, Fireproof Bricks Company has been at the forefront of developing and manufacturing high-quality fireproof bricks for various applications, including industrial furnaces, kilns, fireplaces, and chimneys. With a state-of-the-art production facility and a team of experienced engineers and technicians, the company has set the standard for fireproof bricks that are not only durable and reliable but also environmentally friendly.One of the key factors that sets Fireproof Bricks Company apart from its competitors is its relentless commitment to research and development. The company continuously invests in cutting-edge technologies and advanced manufacturing processes to improve the performance and sustainability of its products. Through extensive testing and analysis, Fireproof Bricks Company has been able to develop fireproof bricks that exceed industry standards in terms of fire resistance, thermal insulation, and environmental impact.Furthermore, Fireproof Bricks Company has been proactive in incorporating sustainable practices into its operations. The company has implemented a comprehensive waste management system to minimize its environmental footprint and maximize resource efficiency. By utilizing recycled materials and reducing energy consumption, Fireproof Bricks Company has been able to offer eco-friendly fireproof bricks that meet the demands of environmentally conscious consumers and businesses.In addition to its commitment to innovation and sustainability, Fireproof Bricks Company has also distinguished itself through its dedication to customer satisfaction. The company takes pride in providing personalized service and technical support to its clients, ensuring that they receive the right fireproof bricks for their specific needs and applications. With a global network of distributors and partners, Fireproof Bricks Company has established itself as a trusted source for high-quality fireproof bricks worldwide.Looking ahead, Fireproof Bricks Company is poised to continue leading the industry with its innovative technology and sustainable practices. The company remains focused on advancing its product offerings and exploring new opportunities to further enhance the performance and environmental impact of fireproof bricks. By staying true to its core values of quality, innovation, and sustainability, Fireproof Bricks Company is well-positioned to shape the future of fire protection and construction materials.In conclusion, Fireproof Bricks Company has earned its reputation as a pioneer and leader in the fireproof bricks industry. With a strong track record of innovation, quality, and sustainability, the company has set the standard for high-performance and environmentally friendly fireproof bricks. As it continues to push the boundaries of technology and sustainability, Fireproof Bricks Company is poised to remain at the forefront of the industry for years to come.

Top Quality Graphite Electrode Available Now - Find Out More!

UHP Graphite Electrode has been making headlines in the industry for its exceptional performance and reliability. These high-quality electrodes are manufactured by a leading company in the field of carbon and graphite products. The company has a strong reputation for delivering top-notch products and has established itself as a trusted supplier in the global market.The UHP Graphite Electrode is a crucial component in electric arc furnace (EAF) steelmaking, as it is used to conduct electricity and generate the intense heat required to melt scrap steel and other raw materials. The electrodes are subjected to extreme temperatures and mechanical stress during the steelmaking process, so they need to be of the highest quality to ensure efficient and consistent performance.The company's UHP Graphite Electrodes are engineered to withstand these harsh conditions, offering superior thermal conductivity, high resistance to oxidation, and excellent mechanical strength. These properties make them an ideal choice for demanding steelmaking applications, where performance and reliability are paramount.In addition to their exceptional technical characteristics, the UHP Graphite Electrodes manufactured by the company are also renowned for their consistency and uniformity. Each electrode undergoes rigorous quality control measures to ensure that it meets the highest standards, and the company's state-of-the-art manufacturing facilities are equipped with the latest technology to guarantee precision and reliability in every product.Furthermore, the company is committed to sustainability and environmental responsibility, ensuring that their UHP Graphite Electrodes are produced in an eco-friendly manner. They adhere to strict environmental regulations and actively seek ways to minimize their carbon footprint throughout the production process.The company's dedication to quality, performance, and sustainability has earned them a strong reputation in the industry, and their UHP Graphite Electrodes are widely recognized for their reliability and efficiency. With a focus on innovation and continuous improvement, the company continues to invest in research and development to further enhance the performance and capabilities of their products.In addition to their high-quality products, the company also provides excellent customer service and technical support, ensuring that their clients receive the assistance they need to maximize the performance of their UHP Graphite Electrodes. Their team of experts is dedicated to understanding the specific requirements of each customer and offering tailored solutions to meet their individual needs.As a global leader in the carbon and graphite industry, the company has established a strong presence in key markets around the world, supplying their UHP Graphite Electrodes to steelmakers and foundries across the globe. Their extensive distribution network and strategic partnerships enable them to deliver their products efficiently and effectively, ensuring that they meet the demands of their customers wherever they may be.In conclusion, the company's UHP Graphite Electrodes are a testament to their commitment to quality, performance, and sustainability. With a focus on innovation and customer satisfaction, they have solidified their position as a trusted supplier in the industry, and their products continue to play a vital role in the success of steelmaking operations worldwide.

Strong and Durable Acid Resistant Castable for Industrial Use

Acid Resistant Castable, the Leading Solution for Demanding Industrial EnvironmentsIndustries that handle strong acids and gas emissions require the most innovative materials to withstand the harsh and corrosive environment. For more than two decades, Acid Resistant Castable (ARC) has been at the forefront of manufacturing such solutions. ARC has grown to become an international reference in the production of special concrete, serving a wide range of industries, including petrochemicals, electricity generation, and the pharmaceutical industry.ARC is renowned for its excellent chemical resistance, mechanical properties, and durability, making it ideal for hostile environments. Its key features include:Resistance to high temperatures: Acid Resistant Castable can withstand extreme temperature fluctuations from -150°C to +1800°C. It is designed to maintain chemical stability and mechanical strength while exposed to harsh conditions, ensuring top performance.Exceptional chemical resistance: ARC can resist attacks from a wide range of acids, including sulfuric acid, hydrochloric acid, nitric acid, and other strong acids. This resistance makes it stand out from regular concrete, which is easily corroded by such substances.Superb mechanical strength: Acid Resistant Castable's unique strength properties enable it to hold up against external forces, such as compression, bending, and impact.Ease of installation: One of the main benefits of ARC is its ease of installation. It is easy to mix and install, with no need for vibration, which reduces installation time and costs.ARC ApplicationsThe demands of modern industry require reliable, efficient, and long-term solutions that meet the most stringent safety and environmental requirements. ARC is an essential ingredient in numerous industrial applications, including:Chimneys and furnacesThe chemical industriesIncinerators, kilns, and reactorsPower plants and thermal energy productionPetrochemicals and fertilizer manufacturingWaste management facilitiesPharmaceuticals and healthcareMolten metal handlingFor example, in the petrochemical industry, ARC is widely used in acid storage reservoirs, reaction vessels, distillation columns, and other installations that require high-temperature and strong acid-resistant materials.The production of Acid Resistant CastableStarting with an advanced proprietary mixture of various minerals, together with high-purity chemical components, the production of ARC uses a unique manufacturing process. The different minerals undergo an intensive grinding process to obtain a precise particle size distribution to guarantee maximum strength.ARC production process is a precise and strictly controlled system with a high level of quality assurance. The production line includes modern facilities that can control temperatures up to 2500°C, ensuring the complete, homogenous calcination of the raw materials. The end result is a high-density, corrosion-resistant material that meets the most rigorous safety standards.Benefits and environmental protectionARC offers a vast array of benefits, including the reduced environmental impact of industrial processes as it aids in reducing the emission of toxic and hazardous gases. The durability and chemical resistance of ARC ensure long-term usage, reducing the amount and frequency of material replacements. This significantly reduces the amount of waste materials in landfill sites. At the same time, manufacturing processes support the principles of 'green chemistry' that emphasizes minimal environmental impact during the manufacturing process.In conclusionIn the modern era, industrial processes must balance operational efficiency with environmental responsibility. Chemical resistance, durability, and strength are fundamental features that industry demands from products used in aggressive industrial environments. ARC meets all such demands and requirements. ARC's qualities make it a versatile solution suitable for use across several industries. Its benefits also include being environmentally friendly, and by reducing waste and toxic emissions published into the environment, ARC proves itself to be a sustainable solution, while its ease of installation and long-term usage allows for cost-effective budget planning. With over two decades of serving the world’s industries, Arc has become a synonym for quality, reliability, and trust, and personal commitment to each project.

Discover Effective Tips for Preserving Refractory Cement and Extending Its Lifespan

Saving Refractory Cement Revolutionizes the Construction IndustryWhen it comes to construction materials, durability and reliability are two crucial factors that determine the longevity of a structure. Over the years, numerous innovations have been introduced to improve the quality and performance of building materials. However, one company has taken it a step further by developing a game-changing product that has revolutionized the construction industry - Saving Refractory Cement.Saving Refractory Cement, developed by a leading company in the field, is a high-quality refractory material specifically designed to withstand extreme temperatures and withstand the test of time. With its exceptional properties, this innovative cement has become a go-to choice for construction professionals worldwide.With a focus on sustainability and environmental consciousness, the manufacturers of Saving Refractory Cement have devised a unique formula that significantly reduces carbon emissions during the production process. This makes it an ideal choice for companies and individuals striving to make environmentally responsible construction choices.The exceptional performance of Saving Refractory Cement lies in its high resistance to thermal shock, excellent strength, and exceptional chemical resistance. These properties make it suitable for a wide range of applications, from lining furnaces and kilns to industrial boilers and chimneys. Its ability to withstand extreme temperatures makes it invaluable in industries where high heat is a daily occurrence.Unlike traditional refractory cement, Saving Refractory Cement requires less maintenance and repair. Its longevity ensures that structures built with this innovative material remain intact for years, reducing the need for constant upkeep, and saving businesses both time and money. The durability of Saving Refractory Cement not only enhances the safety of structures but also increases their lifespan, making it a cost-effective choice for all construction projects.Furthermore, the ease of application of Saving Refractory Cement has captivated contractors and builders alike. Its high workability allows for efficient and quick installation, reducing labor costs significantly. Additionally, its versatility enables it to be used in various construction scenarios, further adding to its appeal.The success and popularity of Saving Refractory Cement have made it an essential material in numerous industries, including steel production, glass manufacturing, and power generation. Its ability to withstand extreme temperatures makes it indispensable in these sectors, where maintaining high heat resistance is paramount.In addition to its exceptional properties, Saving Refractory Cement has gained a strong reputation for its commitment to customer satisfaction. The company behind this revolutionary cement provides comprehensive technical support, ensuring that clients receive expert advice on its installation and maintenance. This commitment to excellence has fostered strong relationships with contractors, leading to repeat business and a loyal customer base.As the construction industry continues to evolve, innovation in building materials remains a driving force. Saving Refractory Cement has emerged as a front-runner in this regard, revolutionizing the way structures are built and providing a sustainable and durable solution for construction needs.In conclusion, Saving Refractory Cement has transformed the construction industry with its exceptional properties, environmental consciousness, and commitment to customer satisfaction. Its ability to withstand extreme temperatures, reduced carbon emissions, and ease of application have made it a top choice for construction professionals worldwide. Furthermore, its longevity and cost-effectiveness make it an ideal option for businesses looking to create sustainable structures. With its revolutionary approach, Saving Refractory Cement is undoubtedly reshaping the future of the construction industry.