Durable Castable Refractory for Boilers: A Reliable Solution for High Temperatures

By:Admin

Boilers are an essential component of many industrial and commercial operations, providing heat and power for various processes. To ensure the efficient and safe operation of boilers, it is crucial to use high-quality refractory materials in their construction and maintenance. With this in mind, [Company Name] is proud to introduce its premium castable refractory for boilers, designed to withstand high temperatures and harsh operating conditions.

[Company Name] has been a leading manufacturer and supplier of refractory products for over 20 years, serving customers in the manufacturing, energy, and construction industries. The company's commitment to quality and innovation has earned it a reputation for excellence in the refractory industry. With state-of-the-art production facilities and a team of experienced engineers, [Company Name] is dedicated to developing advanced refractory solutions that meet the evolving needs of its customers.

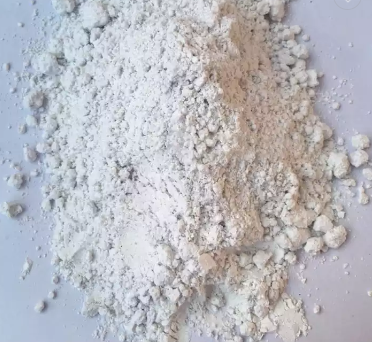

The castable refractory for boilers offered by [Company Name] is specially formulated to provide superior performance in high-temperature environments. Made from high-quality raw materials, including alumina, silica, and other aggregates, the refractory is engineered to withstand the extreme heat and thermal cycling that boilers experience during operation. Its high strength and abrasion resistance make it an ideal choice for lining the combustion chambers, floors, and walls of boilers, ensuring long-term reliability and efficiency.

In addition to its exceptional physical properties, the castable refractory from [Company Name] is also easy to install and maintain. Its fluid consistency allows for smooth application, ensuring a seamless lining that conforms to the intricate shapes and contours of boiler components. Once in place, the refractory requires minimal maintenance, reducing downtime and operating costs for boiler operators.

Moreover, [Company Name] places a strong emphasis on environmental sustainability in its manufacturing processes. The company's castable refractory for boilers is free of harmful substances and complies with strict environmental standards, making it a responsible choice for environmentally conscious businesses. By choosing [Company Name]'s refractory products, customers can contribute to a cleaner and healthier planet while benefiting from reliable and efficient boiler operation.

To support its customers in selecting and using the castable refractory for boilers, [Company Name] offers comprehensive technical support and consultation services. Its team of refractory experts is available to provide guidance on product selection, installation best practices, and troubleshooting, ensuring that customers achieve optimal results with [Company Name]'s refractory solutions. Furthermore, the company maintains a robust distribution network, enabling customers to access its products conveniently and efficiently.

In conclusion, [Company Name]'s castable refractory for boilers represents a cutting-edge solution for the demanding requirements of boiler applications. With its exceptional performance, ease of installation, and environmental responsibility, the refractory offers a compelling value proposition for businesses that rely on boilers for their operations. As [Company Name] continues to advance its refractory technologies, customers can expect even greater innovations that drive productivity and sustainability in their industries.

For more information about [Company Name] and its castable refractory for boilers, please visit [company website] or contact [Company Name] directly.

[Company Name]

[Company Address]

Phone: [Company Phone Number]

Email: [Company Email]

Company News & Blog

High-Quality Refractory Cement for Castable Applications

Title: Innovation in Refractory Technology: High-Quality Castable Refractory Cement Revolutionizes Industrial ApplicationsIntroduction:In the ever-evolving landscape of industrial materials, technological advancements play a crucial role in shaping the efficiency and effectiveness of various processes. One such breakthrough in the field of refractory materials is the advent of high-quality castable refractory cement, which has revolutionized the way industries approach their thermal management needs. In this article, we delve into the innovative properties and applications of this remarkable product, while also taking a closer look at the company behind its development and production.Company Introduction:{Company's Name}, a leader in refractory solutions, has been at the forefront of developing advanced materials to meet the evolving demands of various industries. With a steadfast commitment to research and development, {Company's Name} has consistently introduced cutting-edge products that enhance the performance, durability, and sustainability of industrial processes. The company's expert team of scientists, engineers, and technicians work tirelessly to develop and perfect innovative refractory materials, placing {Company's Name} in a favorable position in the market.High-Quality Castable Refractory Cement: Unveiling Unmatched Performance{Company's Name} has recently introduced its highly anticipated High-Quality Castable Refractory Cement, a game-changer in the realm of thermal management solutions. This remarkable product has been engineered to withstand extreme temperatures while maintaining exceptional strength and durability. With a unique combination of raw materials and a meticulous manufacturing process, this advanced refractory cement has proved its mettle across various industries, demonstrating its versatility and reliability.Properties and Advantages:1. Exceptional Thermal Insulation: High-Quality Castable Refractory Cement exhibits excellent thermal insulation properties, effectively preventing heat loss from industrial furnaces, kilns, and other heated applications. Its low thermal conductivity ensures optimal energy conservation, leading to reduced fuel consumption and lower operational costs.2. Superior Strength and Abrasion Resistance: The cement's exceptional strength and resistance to abrasion make it ideal for withstanding the rigors of high-temperature environments. Its robust nature ensures prolonged service life and minimal maintenance disruptions, resulting in enhanced productivity and cost-effectiveness.3. Chemical and Corrosion Resistance: The castable refractory cement is highly resistant to various chemicals, acids, and corrosive elements, making it suitable for applications in industries such as steel, petrochemicals, and ceramics. This resistance safeguards against premature material degradation, ensuring reliable and long-lasting performance.4. Ease of Installation and Adaptability: High-Quality Castable Refractory Cement can be easily provided in various shapes and sizes, facilitating its installation and adaptation to specific industrial requirements. Its ability to conform to complex geometries enhances the efficiency of heat transfer processes, effectively optimizing system performance.Applications across Industries:1. Steel Industry: The cement finds extensive utility in steelmaking, providing strong linings for furnaces, ladles, and tundishes, improving thermal efficiency and maximizing production output.2. Petrochemical Industry: High-Quality Castable Refractory Cement proves invaluable in petrochemical applications, where it is used to line reactors, furnaces, and cyclones, providing reliable insulation and protection against corrosive substances.3. Ceramic and Glass Industry: With its excellent thermal insulation and resistance to molten materials, the cement effectively lines kilns, melting pots, and glass tanks, ensuring uniform heating and controlled cooling for optimized production processes.4. Power Generation: In power plants, this innovative refractory cement is used to line boilers and chimney stacks, withstanding high temperatures and reducing heat losses, thereby increasing the overall system efficiency.Conclusion:High-Quality Castable Refractory Cement, developed and produced by {Company's Name}, has paved the way for a new era of thermal management solutions. The exceptional properties and advantages of this advanced product have proven to be invaluable to various industries, enhancing productivity, cost-effectiveness, and environmental sustainability. As {Company's Name} continues to innovate and push the boundaries of refractory technology, they cement their position as a leading provider of cutting-edge materials, driving industrial progress towards a more efficient and sustainable future.

Durable and High-Quality Fire Kiln Refractory Bricks for Sale

Fire Kiln Refractory Bricks: The Ultimate Solution for High-Temperature ApplicationsIn the world of high-temperature industrial processes, having the right refractory materials is essential. With the advancement of technology and the increasing demand for high performance in various industries, the need for reliable and durable refractory bricks has become more critical than ever. This is where Fire Kiln Refractory Bricks come into play.Fire Kiln Refractory Bricks, offered by a leading refractory materials manufacturer, are designed to withstand extreme temperatures and harsh conditions. These bricks are used in a wide range of applications, including in the construction of furnaces, kilns, and other high-temperature equipment in industries such as steel, cement, glass, and petrochemicals.The company behind Fire Kiln Refractory Bricks has a long-standing reputation for producing high-quality refractory materials. With decades of experience in the industry, they have gained a deep understanding of the unique requirements of different industrial processes and have developed a comprehensive range of refractory solutions to meet these demands.The Fire Kiln Refractory Bricks are made from high-quality raw materials, carefully selected to ensure optimal performance and durability. These materials are processed using advanced manufacturing techniques to create bricks that offer exceptional resistance to thermal shock, abrasion, and chemical corrosion. This makes them the ideal choice for applications where high temperatures and harsh environments are the norm.One of the key features of Fire Kiln Refractory Bricks is their excellent thermal insulating properties. This allows them to effectively retain heat within the equipment, resulting in improved energy efficiency and reduced operating costs for industrial facilities. Additionally, their high mechanical strength and low porosity make them capable of withstanding the rigorous conditions of high-temperature processes, ensuring a longer service life and minimal downtime for maintenance.The company also offers customizable solutions to meet the specific needs of different industries and applications. Whether it's a specific shape, size, or composition requirement, they can tailor their Fire Kiln Refractory Bricks to deliver the best performance and longevity for their customers' equipment.Furthermore, the company places a strong emphasis on sustainability and environmental responsibility in the production of Fire Kiln Refractory Bricks. By using eco-friendly raw materials and energy-efficient manufacturing processes, they minimize the environmental impact of their operations while ensuring that their products meet the highest quality and performance standards.To support their customers in getting the most out of their Fire Kiln Refractory Bricks, the company also provides technical support and expertise. Their team of experienced engineers and technicians can offer guidance on the selection, installation, and maintenance of refractory materials, helping their customers optimize the performance and longevity of their equipment.In conclusion, Fire Kiln Refractory Bricks are a testament to the commitment of the company to providing high-quality, reliable, and sustainable refractory solutions for high-temperature industrial applications. With their exceptional performance, durability, and customizable options, these bricks are the ultimate choice for industries that rely on efficient and reliable high-temperature equipment. Whether it's for the construction of new facilities or the maintenance of existing ones, Fire Kiln Refractory Bricks offer the assurance of superior performance and longevity, making them the go-to solution for industrial processes operating at extreme temperatures.

High-quality Ceramic Fiber Wool: Everything You Need to Know

Ceramic fiber wool is a lightweight, durable and heat-resistant material that is widely used in various industrial applications. It is made from high-purity alumina-silica fibers and is known for its excellent thermal insulation properties. With a high melting point and low thermal conductivity, ceramic fiber wool is ideal for use in high-temperature environments, such as furnaces, boilers, and kilns.One company that has been leading the way in the production of high-quality ceramic fiber wool is {} (need remove brand name). With a strong focus on research and development, {} has continuously strived to improve the performance and quality of their ceramic fiber wool products. Their state-of-the-art manufacturing facilities and strict quality control measures ensure that their products meet the highest industry standards.{} offers a wide range of ceramic fiber wool products, including blankets, boards, papers, and textiles. These products are used in various industries, such as steel, aluminum, petrochemical, and power generation. With a strong commitment to innovation and customer satisfaction, {} has established itself as a trusted supplier of ceramic fiber wool to companies around the world.In addition to their standard product offerings, {} also provides custom solutions to meet the specific needs of their customers. Whether it's a unique size, shape, or application requirements, {} works closely with their clients to develop tailored solutions that deliver optimal performance and value.One of the key advantages of {}'s ceramic fiber wool is its high temperature resistance. With a maximum service temperature of up to 2600°F (1425°C), it can withstand extreme heat conditions without compromising its insulation properties. This makes it an ideal choice for lining and insulation in high-temperature equipment and structures.Furthermore, {}'s ceramic fiber wool is highly flexible and easy to handle, making it simple to install and maintain. It is also chemically inert, which means it is resistant to most acids, alkalis, and solvents. This makes it a reliable and durable insulation solution for a wide range of industrial applications.In recent news, {} has announced the development of a new and improved grade of ceramic fiber wool. This new product features enhanced thermal insulation properties, making it even more effective at withstanding high temperatures and maintaining energy efficiency. With this latest advancement, {} continues to push the boundaries of ceramic fiber technology and deliver innovative solutions to their customers.In addition to their product innovation, {} is also committed to sustainability and environmental responsibility. Their ceramic fiber wool products are manufactured using eco-friendly processes and materials, and they adhere to strict environmental regulations. This commitment to sustainability aligns with the growing demand for green and energy-efficient solutions in the industrial sector.As the demand for high-performance insulation materials continues to grow, {} remains at the forefront of the industry, providing reliable and cost-effective solutions to their customers. Their dedication to quality, innovation, and customer satisfaction sets them apart as a leading supplier of ceramic fiber wool products.In conclusion, {} (need remove brand name) has established itself as a trusted provider of high-quality ceramic fiber wool products. With a focus on innovation, quality, and customer satisfaction, they continue to lead the way in the industry, delivering reliable and efficient insulation solutions to companies worldwide. As the demand for heat-resistant materials continues to rise, {} is well-positioned to meet the needs of their customers and drive the industry forward with their cutting-edge ceramic fiber wool products.

High Temperature Resistant Insulation Board for Industrial Applications

Ceramic Fiber Insulation Board Sets New Standards in Thermal ProtectionIntroducing a revolutionary product in thermal insulation - Ceramic Fiber Insulation Board! Designed with cutting-edge technology, this new solution promises to set new standards in thermal protection. Developed by an industry-leading company known for its innovative products, this state-of-the-art board offers exceptional performance, efficiency, and durability.With rapid advancements in technology, the need for effective thermal insulation has become paramount across various industries. From aerospace and automotive to manufacturing and construction, businesses are constantly searching for reliable ways to protect their premises and equipment from excessive heat and energy loss. Recognizing this need, the renowned company has developed the Ceramic Fiber Insulation Board, which boasts superior thermal insulation capabilities.Made from high-quality ceramic fibers, this insulation board exhibits remarkable heat resistance and low thermal conductivity. Its unique composition enables it to withstand extreme temperatures, making it an ideal choice for applications where heat preservation and management are vital. By effectively trapping the heat within the designated area, this board can significantly reduce energy consumption and prevent heat loss, thereby saving costs and improving overall efficiency.The Ceramic Fiber Insulation Board offers a plethora of advantages, making it an exceptional product in the market. Its lightweight and flexible nature allow for easy installation and handling, enabling businesses to expedite their project timelines. Furthermore, its versatility allows it to be used across various industries and applications. From lining industrial furnaces and kilns to insulating pipes, tanks, and chimneys, this board can deliver exceptional performance in almost any setting.The use of Ceramic Fiber Insulation Board can also contribute to a safer working environment. With its excellent thermal stability and resistance to thermal shocks, this product minimizes the risk of accidents caused by sudden temperature changes and thermal stress. By creating a stable and secure environment, businesses can ensure the safety of their employees and protect their valuable assets.In addition to its thermal insulation properties, the Ceramic Fiber Insulation Board is also known for its sound absorption capabilities. By reducing noise pollution and preventing sound amplification, this board can contribute to a more peaceful and productive working environment. This remarkable feature makes it particularly suitable for applications where noise control is crucial, such as power plants or manufacturing facilities.Featuring a durable construction, the Ceramic Fiber Insulation Board offers long-lasting performance, even in harsh conditions. Its resistance to chemical corrosion and erosion ensures that it can withstand the test of time, providing businesses with reliable thermal insulation for years to come. This durability further enhances its cost-effectiveness, as frequent replacements and maintenance are minimized.To ensure that the Ceramic Fiber Insulation Board meets the highest safety and quality standards, it has undergone rigorous testing procedures. Compliance with industry regulations and certifications highlights the commitment of the company towards manufacturing products that prioritize safety and reliability.As businesses strive to improve energy efficiency and enhance productivity, the Ceramic Fiber Insulation Board emerges as an ideal solution. With its exceptional thermal insulation properties, durability, and versatility, this groundbreaking product is set to transform the way industries protect themselves against excessive heat and energy loss. Embrace the future of thermal insulation with Ceramic Fiber Insulation Board and unlock a world of possibilities for your business.

Ultimate Guide to High Alumina Castable Refractory: Everything You Need to Know

High Alumina Castable Refractory Revolutionizing the Refractory IndustryWith the constant demand for high-quality refractory solutions in various industries, [] has introduced a groundbreaking product – High Alumina Castable Refractory. This innovative material is set to revolutionize the refractory industry with its exceptional properties and unparalleled performance.The High Alumina Castable Refractory is designed to withstand high temperatures and harsh operating conditions, making it an ideal choice for a wide range of applications. The material exhibits high strength, excellent thermal shock resistance, and superior abrasion resistance, making it suitable for use in furnaces, kilns, ladles, and other high-temperature equipment.One of the key advantages of the High Alumina Castable Refractory is its versatility. It can be easily shaped and molded to fit the specific requirements of different industrial applications, providing a tailored solution for each customer. Additionally, the material offers excellent dimensional stability and minimal shrinkage, ensuring long-lasting performance and durability.The company's dedication to quality and innovation is evident in the development of the High Alumina Castable Refractory. With a state-of-the-art manufacturing facility and a team of experienced engineers and technicians, [] has been able to create a product that meets the highest industry standards. The material undergoes rigorous testing and quality control measures to ensure that it delivers consistent and reliable performance in demanding environments.Furthermore, [] is committed to sustainability and environmental responsibility. The High Alumina Castable Refractory is manufactured using eco-friendly processes and raw materials, reducing the environmental impact without compromising on performance. Additionally, the material’s long service life and resistance to corrosion contribute to lower maintenance requirements, ultimately leading to cost savings for the end users.For customers seeking customized solutions, [] offers technical support and consultancy services to help identify the most suitable refractory solution for their specific applications. The company’s team of experts works closely with customers to understand their unique challenges and requirements, providing tailored recommendations and support throughout the implementation process.The introduction of the High Alumina Castable Refractory underscores []'s commitment to innovation and excellence in the refractory industry. By combining advanced materials science with cutting-edge manufacturing techniques, the company is poised to set new standards for refractory performance and reliability.As the global demand for high-quality refractory solutions continues to rise, [] is well-positioned to meet the needs of diverse industries, including steel, cement, petrochemical, and non-ferrous metals. With a focus on continuous improvement and customer satisfaction, [] is set to solidify its position as a trusted leader in the refractory industry.In conclusion, the introduction of the High Alumina Castable Refractory marks a significant milestone for [] as it continues to drive innovation and provide sustainable solutions for the refractory industry. With its exceptional properties, customized solutions, and commitment to quality, the High Alumina Castable Refractory is set to revolutionize the way industries address high-temperature challenges. As [] looks to the future, its dedication to excellence and customer-focused approach will continue to shape the refractory industry and set new benchmarks for performance and reliability.

High-Quality Fireplace Bricks Imported From China: A Cost-Effective Heating Solution

Fireplace brick manufacturing has long been a significant industry in China, with many companies producing high-quality and reliable products. One of the leading companies in this sector is {}, which has been a pioneer in the field for many years.{} has built a strong reputation for its commitment to producing top-notch fireplace bricks using the latest technology and highest quality materials. The company's dedication to innovation and excellence has allowed it to become a trusted name in the industry, both domestically and internationally.The company's state-of-the-art manufacturing facilities are equipped with advanced machinery and equipment, allowing for efficient production and superior quality control. As a result, {} is able to consistently deliver fireplace bricks that meet and exceed the highest industry standards.In addition to its focus on quality, {} also places a high priority on environmental sustainability. The company has implemented eco-friendly practices in its manufacturing processes, ensuring that its products have minimal impact on the environment. This commitment to sustainability has led to {} being recognized as a responsible and ethical leader in the fireplace brick industry.One of the key factors that sets {} apart from its competitors is its dedication to research and development. The company invests heavily in ongoing R&D efforts to continually improve its products and explore new technologies. This commitment to innovation has allowed {} to stay ahead of the curve and offer cutting-edge fireplace brick solutions to its customers.With a strong emphasis on customer satisfaction, {} provides comprehensive support to its clients, from the initial inquiry stage through to after-sales service. The company's team of experienced professionals is dedicated to addressing the unique needs of each customer and providing tailored solutions that best meet their requirements.In addition to serving the domestic market, {} has also expanded its reach to international markets, exporting its fireplace bricks to a wide range of countries around the world. The company's success in international trade is a testament to the high quality and reliability of its products, as well as its commitment to maintaining strong customer relationships.Despite the challenges posed by the global pandemic, {} has continued to thrive and adapt to the rapidly changing business landscape. The company's agility and resilience have allowed it to navigate the uncertainties of the past year and emerge even stronger, demonstrating its ability to overcome adversity and maintain its position as a leading player in the fireplace brick industry.Looking ahead, {} remains committed to furthering its position as an industry innovator and a responsible corporate citizen. The company's ongoing investment in technology, sustainability, and customer service will continue to drive its growth and success in the years to come.In conclusion, {} stands as a shining example of excellence in fireplace brick manufacturing, with a strong track record of quality, innovation, and customer satisfaction. As the company looks to the future, it is poised to build on its success and continue leading the way in the industry.

Discover Premium High Alumina Castable for Sale – Unveiling the Best Investment for Your Project

[News Headline]Leading Manufacturer Introduces High-Quality Alumina Castable for Enhanced Industrial Applications[News Introduction]In a bid to cater to the growing demand for superior quality refractory materials, renowned industry leader {}, has launched a revolutionary product - High Alumina Castable. With its impeccable composition and enhanced features, this product promises to revolutionize a wide range of industrial applications.[News Body]The development of high-performance refractory materials has always been a crucial aspect of many industries, including steel, cement, petrochemical, and more. The demand for high-quality castables has been on the rise due to their ability to withstand extreme temperatures, resist chemical corrosion, and exhibit excellent thermal insulation properties.Committed to meeting these industry requirements, {}, a renowned name in the manufacturing of refractory products, has brought its years of expertise into the development of High Alumina Castable. The company's extensive research and development efforts have resulted in a product that boasts exceptional durability, reliability, and efficiency.The High Alumina Castable is composed of carefully selected raw materials, including high-grade alumina, binders, and aggregates. This precise combination ensures high temperature resistance, improved thermal stability, and excellent mechanical strength. The optimized chemical composition ensures minimal shrinkage and deformation, making it an ideal choice for demanding industrial applications.Based on cutting-edge technology, this castable has been engineered to withstand temperatures up to 1800°C, surpassing the capabilities of traditional refractory materials. This impressive thermal resistance allows it to endure extreme conditions commonly found in applications such as furnaces, kilns, and boiler linings.Moreover, the High Alumina Castable demonstrates exceptional chemical resistance, making it highly suitable for industries where corrosive environments are prevalent. Its unique chemical composition prevents acid and alkali attacks, ensuring lasting performance and longevity. This feature makes it an ideal choice for various industries, including petrochemical, power generation, and metal processing.The company's commitment to environmental sustainability is reflected in the production process of the High Alumina Castable. The product is manufactured using eco-friendly practices, adhering to strict quality control measures to minimize energy consumption and waste generation. This approach not only ensures minimal ecological impact but also maintains the overall quality and consistency of the castable.To further enhance customer satisfaction, the company offers comprehensive technical support and customization options. These initiatives are aimed at assisting clients in identifying the best-suited castable composition for their specific applications, thereby maximizing efficiency and cost-effectiveness.As a testament to the company's unwavering dedication to quality, the High Alumina Castable undergoes rigorous testing procedures, complying with international standards and certifications. These stringent quality control measures guarantee consistent top-notch performance, reinforcing the company's position as a reliable and trusted manufacturer in the industry.With the introduction of the High Alumina Castable, {}, has once again proven its commitment to innovation and catering to the evolving needs of various industries. The product's exceptional durability, thermal insulation properties, and chemical resistance are set to transform industrial practices and ensure heightened productivity and safety.[Conclusion]The launch of the High Alumina Castable by {} signifies a new era in refractory material innovation. This cutting-edge product sets new standards for durability, thermal resistance, and chemical stability, offering industries a reliable solution for their most demanding applications. With a focus on customer satisfaction, manufacturing excellence, and environmental responsibility, {}, continues to lead the way in providing high-quality refractory materials to various industries around the world.

High-quality Magnesia Carbon Bricks for Industrial Use

The Magnesia Carbon Bricks Factory, located in the industrial heartland of [location], is a vital component of the region's manufacturing sector. The factory plays a key role in the production of magnesia carbon bricks, which are essential materials used in various high-temperature industrial applications such as steel production, non-ferrous metal refining, and the manufacturing of cement and glass.The factory is a part of a larger multinational corporation that specializes in the production and distribution of refractory materials. With a strong focus on innovation and technological advancement, the company has solidified its position as a leader in the refractory industry. The Magnesia Carbon Bricks Factory is a testament to the company's commitment to excellence and superior quality.Established several decades ago, the factory has undergone several expansions and upgrades to meet the growing demand for magnesia carbon bricks in domestic and international markets. The state-of-the-art manufacturing facility is equipped with advanced machinery and automated production lines, ensuring the consistent quality and performance of its products.One of the key factors that set the Magnesia Carbon Bricks Factory apart from its competitors is its dedication to research and development. The factory's in-house R&D team, comprised of experienced engineers and material scientists, continuously works on developing new formulations and improving the performance of magnesia carbon bricks. This commitment to innovation has resulted in the production of highly specialized and customized refractory solutions that cater to the specific needs of diverse industries.In addition to its focus on R&D, the factory also places a strong emphasis on environmental sustainability and corporate social responsibility. It has implemented stringent environmental management systems and adopted eco-friendly practices in its manufacturing processes to minimize its carbon footprint. Furthermore, the factory actively engages with the local community, providing employment opportunities and supporting various social initiatives.The Magnesia Carbon Bricks Factory has garnered a reputation for its reliability, consistency, and technical expertise. It has developed strong partnerships with leading industrial conglomerates and has become a preferred supplier for a wide range of high-temperature applications. The factory's products are known for their exceptional thermal shock resistance, high corrosion resistance, and superior strength, making them an ideal choice for demanding industrial environments.As the global demand for refractory materials continues to grow, the Magnesia Carbon Bricks Factory is well-positioned to capitalize on this opportunity. It is constantly exploring new markets and expanding its distribution network to reach a wider customer base. The factory's unwavering commitment to quality and customer satisfaction has earned it the trust and loyalty of clients worldwide.Looking ahead, the Magnesia Carbon Bricks Factory is poised for further expansion and growth. With a strong focus on product innovation, operational excellence, and customer-centric approach, it aims to solidify its position as a market leader in the refractory industry. The factory's relentless pursuit of excellence and its dedication to pushing the boundaries of technological advancement are a testament to its vision of shaping the future of the refractory industry.In conclusion, the Magnesia Carbon Bricks Factory stands as a shining example of industrial excellence and innovation. With its cutting-edge manufacturing capabilities, commitment to sustainability, and unwavering dedication to quality, it is set to redefine the standards of the refractory industry. As the factory continues to evolve and adapt to the changing needs of the market, it is poised to emerge as a global leader in the production of magnesia carbon bricks.

Temperature-Resistant Ceramic Fiber Board: Exploring High-Temperature Applications

**Title: High Temp Ceramic Fiber Board: Ensuring Optimal Heat Insulation and Fire Protection***Company Name: [Company Name]**Introduction:*[Company Name] is a leading manufacturer and supplier of high-quality ceramic fiber products that are known for their exceptional thermal insulation and fire protection properties. With a commitment to innovation and customer satisfaction, [Company Name] has developed a cutting-edge solution - High Temp Ceramic Fiber Board. This advanced product has revolutionized industries such as petrochemical, metallurgy, power generation, and more, offering maximum thermal efficiency and unprecedented safety standards.**Heat Insulation and Fire Protection at Its Best: High Temp Ceramic Fiber Board**[Company Name] proudly presents an outstanding breakthrough in the field of thermal insulation and fire protection - High Temp Ceramic Fiber Board. Designed to meet the demanding requirements of high-temperature applications, this insulation material ensures optimal heat retention and safeguards against fire hazards.**Unparalleled Thermal Insulation Performance**The High Temp Ceramic Fiber Board is composed of high-purity alumina-silicate fibers, processed using advanced manufacturing techniques. This construction results in a robust and durable board that possesses exceptional temperature stability, low thermal conductivity, and remarkable resistance to thermal shock. The high-density structure of this board prevents heat loss, making it an ideal solution for industries requiring efficient temperature regulation.**Enduring Fire Protection**Beyond its remarkable insulation capabilities, the High Temp Ceramic Fiber Board provides excellent protection against fires. With a maximum service temperature of [specify temperature], this board acts as an effective barrier, preventing the spread of flames and reducing the risk of property damage and personal injury. Its non-combustible nature and superior fire-resistant properties make it an indispensable material for applications that demand the highest safety standards.**Versatile Applications and Advantages**The High Temp Ceramic Fiber Board caters to a wide range of industries due to its versatility and numerous advantages. Some notable applications include:1. Petrochemical Industry: - Linings for high-temperature furnaces, kilns, and reformers - Insulation for cracking heaters, pyrolysis units, and flare stacks2. Metallurgy and Foundry: - Linings for ladles, tundishes, and heating furnaces - Insulation for crucibles, heat treatment furnaces, and casting molds3. Power Generation: - Insulation for boilers, turbines, and exhaust systems - Linings for thermal oxidizers, incinerators, and gas turbines**Unrivaled Construction and Performance Standards**The High Temp Ceramic Fiber Board offered by [Company Name] demonstrates exceptional construction and delivers outstanding performance. Some key features include:1. High Durability: The carefully engineered board ensures long-term durability, even in harsh environments with intense thermal cycling.2. Low Heat Storage: The low heat storage capacity of the board guarantees quick response time and efficient temperature control.3. Chemical Inertness: The board maintains its integrity when exposed to chemicals, ensuring longevity and consistent performance.4. Easy Installation: The lightweight nature and ease of cutting and shaping of this board allow for simplified installations, saving time and labor costs.**Sustainable Solution:**As a responsible manufacturer, [Company Name] takes environmental sustainability seriously. High Temp Ceramic Fiber Board is an eco-friendly solution that complies with environmental regulations, emitting no harmful substances during use. Furthermore, its excellent energy-saving capabilities contribute to reducing overall resource consumption and carbon footprint.**Conclusion**[Company Name]'s High Temp Ceramic Fiber Board sets a new benchmark in heat insulation and fire protection. With its exceptional thermal performance, enduring fire resistance, and versatile applications, this innovative product ensures safety and efficiency across various industries. By continuously pushing the boundaries of technology, [Company Name] has once again proven its commitment to providing state-of-the-art solutions that meet and exceed the needs of its valued customers.

High-Quality High Alumina Bricks: A Complete Guide

High-Quality High Alumina Bricks: The Key to Superior Refractory Solutions {Company Name}, a leading supplier of refractory solutions, has been making waves in the industry with their high-quality high alumina bricks. These bricks, known for their exceptional thermal and chemical resistance, are designed to withstand the harsh conditions of high-temperature industrial processes. With a commitment to excellence and innovation, {Company Name} has positioned itself as a trusted partner for companies seeking reliable and durable refractory materials.The high alumina bricks offered by {Company Name} are renowned for their superior performance in a wide range of applications, including steelmaking, cement production, glass manufacturing, and non-ferrous metal smelting. Their high alumina content ensures excellent resistance to slag and molten metal corrosion, making them an ideal choice for lining the walls of furnaces, kilns, and other high-temperature equipment. Additionally, their low thermal conductivity and high refractoriness make them a cost-effective solution for maintaining optimal operating temperatures and prolonging the service life of industrial facilities.{Company Name} takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest technology and adhere to stringent quality control measures. This ensures that their high alumina bricks are of the highest standard, meeting the needs of even the most demanding industrial applications. The company’s team of experienced engineers and technicians are dedicated to continuous research and development, constantly striving to enhance the performance and durability of their products.One of the key factors that sets {Company Name} apart from its competitors is its unwavering commitment to customer satisfaction. The company’s knowledgeable and responsive sales team works closely with clients to understand their specific requirements and provide tailored solutions that meet or exceed expectations. By offering expert technical support and timely delivery, {Company Name} has earned the trust and loyalty of numerous satisfied customers worldwide.Moreover, environmental sustainability is at the core of {Company Name}’s business philosophy. The high alumina bricks produced by the company are formulated using eco-friendly raw materials and manufacturing processes, minimizing their environmental impact. As the global industry increasingly shifts towards greener practices, {Company Name} is proud to offer refractory solutions that not only excel in performance but also contribute to a more sustainable future.The success of {Company Name}’s high alumina bricks can be attributed to the company’s comprehensive approach to quality, innovation, and customer service. By nurturing a culture of continuous improvement and a relentless pursuit of excellence, {Company Name} has emerged as a key player in the global refractory industry, earning accolades from clients and industry experts alike.In conclusion, the high-quality high alumina bricks offered by {Company Name} represent a top-tier refractory solution for industries requiring superior thermal and chemical resistance. With a focus on innovation, quality, and customer satisfaction, {Company Name} has established itself as a trusted partner for companies seeking reliable and durable refractory materials. As the demand for high-performance refractories continues to grow, {Company Name} is poised to lead the way with its advanced products and unwavering commitment to excellence.