Durable and heat-resistant refractory concrete for industrial applications

By:Admin

One company that has been at the forefront of manufacturing and supplying high-quality Castable Refractory Concrete is {}. With years of experience and expertise in the field of refractory materials, they have been able to develop an innovative and superior product that meets the stringent requirements of modern construction and industrial applications.

The company has a state-of-the-art manufacturing facility equipped with advanced technology and a team of dedicated professionals who ensure that every batch of Castable Refractory Concrete meets the highest standards of quality and performance. Their commitment to research and development has led to the creation of a product that outperforms traditional refractory materials in terms of strength, heat resistance, and longevity.

One of the key advantages of using {}'s Castable Refractory Concrete is its ease of installation. Unlike traditional refractory materials, which often require complex molds and special curing processes, this innovative concrete can be simply cast into place, allowing for faster and more efficient construction. This not only saves time and labor costs but also ensures a consistent and uniform finish that is free from any joints or seams.

In addition to its ease of installation, Castable Refractory Concrete from {} offers exceptional resistance to thermal shock and chemical erosion. This makes it an ideal choice for applications that involve exposure to high temperatures and corrosive environments, such as in kilns, incinerators, and reactors. The product's high density and low porosity further enhance its resistance to heat and chemical attacks, ensuring long-term durability and reliability.

Furthermore, {}'s Castable Refractory Concrete is designed to provide excellent thermal insulation, helping to reduce heat loss and improve energy efficiency in industrial processes. Its superior insulating properties make it a preferred choice for lining furnaces, ovens, and other high-temperature equipment, where maintaining consistent and controlled temperatures is crucial for the production process.

Another notable feature of {}'s Castable Refractory Concrete is its versatility. The product can be customized to meet specific project requirements, allowing for various formulations and additives to enhance its performance in different applications. This flexibility, combined with the company's technical expertise, enables them to provide tailored solutions for a wide range of industrial and construction needs.

With a strong commitment to quality, innovation, and customer satisfaction, {} has established itself as a trusted supplier of Castable Refractory Concrete in the market. The company's dedication to continuous improvement and excellence has earned them a solid reputation for delivering reliable and high-performance products that set industry standards.

In conclusion, Castable Refractory Concrete from {} offers a compelling solution for demanding construction and industrial applications. With its exceptional durability, ease of installation, thermal insulation properties, and versatility, it has become a preferred choice for professionals seeking reliable and long-lasting refractory materials. As the construction industry continues to evolve, the demand for innovative and high-performance products like {}'s Castable Refractory Concrete is expected to grow, driving further advancements and applications in the field.

Company News & Blog

Understanding the Basics of Arc Furnace Electrodes

XYZ Corp, a renowned leader in the manufacturing of specialized industrial equipment, has recently developed a groundbreaking product that is set to revolutionize the steel industry. The company's newly introduced arc furnace electrodes have garnered attention for their exceptional performance, durability, and environmental sustainability. With this innovative solution, XYZ Corp aims to address some of the key challenges faced by steel manufacturers and usher in a new era of efficiency and sustainability.Arc furnace electrodes are essential components used in electric arc furnaces, which are widely employed in steelmaking processes. These electrodes function by transmitting electrical energy through the furnace, thereby generating the high temperatures required for melting steel scrap. Traditional electrodes, however, often suffer from rapid consumption and degradation, leading to frequent replacements and increased production costs. Additionally, the use of certain electrode materials can be detrimental to the environment due to the release of harmful gases during the steelmaking process.Recognizing these challenges, XYZ Corp took up the task of developing a superior electrode solution that would enhance both operational efficiency and environmental sustainability. After years of extensive research and development, the company successfully engineered a new generation of arc furnace electrodes that demonstrate remarkable performance and longevity.The key distinguishing feature of XYZ Corp's arc furnace electrodes is their advanced composition, which combines cutting-edge materials and proprietary formulations. The resulting electrodes exhibit exceptional heat resistance, enabling them to withstand the extreme temperatures and harsh working conditions within arc furnaces. This outstanding resilience significantly reduces the frequency of electrode replacements, translating into substantial cost savings for steel manufacturers.Moreover, the innovative composition of the electrodes has a positive impact on the environment. XYZ Corp's electrodes have been designed to minimize the release of harmful gases, reducing the carbon footprint associated with the steelmaking process. By embracing these sustainable electrodes, steel manufacturers can contribute to global efforts aimed at curbing greenhouse gas emissions and make progress towards a greener future.Additionally, XYZ Corp's arc furnace electrodes boast a unique self-healing feature that further enhances their longevity and performance. Through a process known as auto-regeneration, the electrodes can repair minor damages and extend their lifespan. This remarkable capability not only reduces downtime and maintenance costs but also ensures consistent and uninterrupted steel production.The introduction of XYZ Corp's arc furnace electrodes has sparked enthusiasm and interest among steel manufacturers across the globe. The potential benefits that these electrodes offer range from increased productivity and cost savings to environmental conservation and sustainability. As such, XYZ Corp has witnessed a surge in demand for their groundbreaking product.To meet this growing demand, the company has expanded its manufacturing capabilities and established strategic partnerships with steel manufacturers worldwide. This concerted effort ensures a reliable supply of the electrodes, helping steelmakers optimize their production processes and achieve enhanced operational efficiency.In conclusion, XYZ Corp's arc furnace electrodes have emerged as a game-changer in the steel industry. With their remarkable performance, durability, and eco-friendly attributes, these electrodes have garnered significant attention and demand. Through this innovation, XYZ Corp sets a new benchmark for industrial equipment and demonstrates its commitment to driving sustainable practices within the steelmaking sector.

Latest Updates on Corundum Castable Prices: Key Factors Impacting the Market

[News Headline]Corundum Castable Price Witnesses Fluctuations in the Market, Company Hopes to Capitalize on the Demand[News Body][date]The corundum castable market, one of the key sectors of the refractory industry, has experienced notable price fluctuations in recent times. Demand for corundum castables has remained robust, owing to their exceptional strength, high thermal conductivity, and resistance to various chemicals and temperatures. As a result, the market has observed a surge in prices due to strong demand, supply chain disruptions, and rising raw material costs. Leading companies like [Company Name] are keen to leverage the market dynamics to capitalize on this increased demand.Corundum castable is a type of refractory material utilized in high-temperature applications where extreme abrasion and corrosion resistance are required. Industries such as steel, petrochemicals, ceramics, and glass are major consumers of corundum castables. The strong growth in these industries, coupled with the increasing preference for environmentally friendly and energy-efficient technologies, has propelled the demand for corundum castables.Despite the pandemic-induced economic uncertainty, the corundum castable market has showcased resilience and stability. The demand for corundum castables has remained steady due to ongoing infrastructure projects, especially in developing economies. The construction of modern infrastructures, such as smart cities and industrial complexes, has significantly boosted the demand for corundum castables.However, these market dynamics have also led to a surge in corundum castable prices. The supply chain disruptions driven by lockdowns and restricted trade have affected the availability of raw materials like alumina, silicon carbide, and zirconia required for producing high-quality corundum castables. The increased transportation costs and rising energy expenses further escalated the prices.The fluctuations in corundum castable prices have garnered attention from both industry experts and consumers. In such a scenario, [Company Name], a prominent player in the corundum castable market, aims to make the most of this market situation. With its wide range of corundum castable products, the company remains committed to providing reliable and cost-effective solutions to its clients.[Company Name], with its strong presence and expertise in the refractory industry, has implemented proactive strategies to mitigate the challenges posed by the fluctuating prices. By focusing on efficient sourcing, streamlining production processes, and strengthening the supply chain, the company aims to stabilize prices and ensure a consistent supply for its customers.One of the core strengths of [Company Name] lies in its research and development capabilities. The company is constantly engaged in developing innovative and customized corundum castables that meet the specific requirements of its diverse customer base. This approach has enabled [Company Name] to maintain a competitive edge in the market while addressing the demands for high-quality and cost-effective solutions.The company spokesperson stated, "We understand the concerns of our customers regarding the price fluctuations in the corundum castable market. [Company Name] is committed to providing reliable and affordable solutions without compromising on quality. We are actively working towards stabilizing prices by optimizing our sourcing, production, and distribution processes. Our focus on research and development ensures that our corundum castable products cater to the evolving needs of our customers."As the corundum castable market continues to witness price fluctuations, industry experts anticipate that the demand for these refractory materials will remain on an upward trajectory. [Company Name] is well-positioned to tap into this growing demand by adapting to market dynamics, emphasizing research and development, and providing reliable and cost-effective solutions to its customers.In conclusion, the corundum castable market is undergoing price fluctuations due to various factors such as strong demand, disruptions in the supply chain, and rising raw material costs. However, companies like [Company Name] are leveraging these market dynamics to their advantage by implementing strategies to stabilize prices and provide cost-effective solutions. The promising growth in industries requiring corundum castables indicates a positive outlook for the market, and [Company Name] aims to capitalize on this opportunity to serve its customers better.

High-Quality Refractory Corundum Brick for Industrial Use

Refractory Corundum Brick, a high-quality and durable product, has been the forefront of the refractory industry for many years. It is widely used in various high-temperature industrial applications such as steel-making, cement, and glass industries. With its exceptional resistance to high temperatures, thermal shock, and corrosion, Refractory Corundum Brick has become a preferred choice for many companies around the world.One of the leading manufacturers of Refractory Corundum Brick is a company that has been at the forefront of the refractory industry for decades. The company has built a strong reputation for producing high-quality refractory products that meet the stringent requirements of various industries. With a focus on innovation and continuous improvement, the company has been able to stay ahead of the competition and provide its customers with cutting-edge solutions for their refractory needs.The Refractory Corundum Brick produced by the company is known for its exceptional performance and reliability. It offers high refractoriness, excellent thermal shock resistance, and superior corrosion resistance, making it an ideal choice for the most demanding high-temperature applications. Whether it's lining a steel ladle, a cement kiln, or a glass melting furnace, Refractory Corundum Brick from this company is designed to excel in the most challenging environments.Furthermore, the company takes great pride in its state-of-the-art manufacturing facilities and stringent quality control processes. The production of Refractory Corundum Brick involves the use of high-purity raw materials and advanced manufacturing techniques to ensure the highest level of product quality. Additionally, the company's quality control team conducts rigorous testing and inspections at every stage of the production process to guarantee that the final product meets the highest standards.Aside from its commitment to quality, the company also places a strong emphasis on sustainability and environmental responsibility. In line with this, the company has implemented eco-friendly manufacturing practices and is constantly seeking ways to minimize its environmental impact. This includes the efficient use of resources, responsible waste management, and the development of environmentally friendly products.Moreover, the company's dedication to customer satisfaction sets it apart in the industry. It has a team of experienced and knowledgeable professionals who work closely with customers to understand their specific needs and provide tailored solutions. Whether it's selecting the right refractory product, providing technical support, or offering on-site assistance, the company is committed to delivering exceptional customer service.In addition to its stellar reputation in the industry, the company is also known for its ongoing research and development efforts. It invests heavily in R&D to explore new materials, innovative technologies, and advanced manufacturing processes. This commitment to innovation ensures that the company stays at the forefront of the refractory industry and continues to provide customers with cutting-edge solutions.As a result of its unwavering commitment to excellence, the company has established itself as a trusted partner for businesses in the steel, cement, and glass industries, among others. Its Refractory Corundum Brick has become synonymous with quality, reliability, and performance, and continues to be the go-to choice for companies with the most demanding refractory needs.In conclusion, Refractory Corundum Brick from this leading company is a testament to its dedication to quality, innovation, and customer satisfaction. With a focus on performance, sustainability, and continuous improvement, the company has solidified its position as a leader in the refractory industry and remains committed to providing the best refractory solutions for its customers' evolving needs.

Discover the Benefits and Uses of High Alumina Insulation Bricks

High Alumina Insulation Bricks Showcase Exceptional Quality and Unmatched Insulation Properties[City, Date] – In a groundbreaking announcement, renowned brick manufacturing company [Company Name] has introduced a revolutionary product – high alumina insulation bricks – that are set to redefine the industry standards. With its exceptional quality and unmatched insulation properties, these bricks are poised to take the construction and insulation sectors by storm.Made from a unique blend of high-quality alumina, these insulation bricks are designed to provide superior thermal efficiency and insulation. With ever-increasing energy costs and a growing global focus on sustainability, optimizing insulation is paramount for both residential and commercial buildings. These new high alumina insulation bricks offer a promising solution.Compared to traditional bricks, [Company Name]'s high alumina insulation bricks possess the distinct advantage of significantly reducing heat transfer. The innovative manufacturing process involves carefully selecting and processing raw materials to create a product with superior insulation properties. This results in lower energy consumption, increased energy efficiency, and reduced dependence on artificial heating or cooling systems.One of the key reasons behind the exceptional insulation capabilities of these bricks is their high alumina content. Alumina is a compound known for its remarkable resistance to heat and its excellent insulation properties. By incorporating a relatively higher percentage of alumina while manufacturing these bricks, [Company Name] has achieved a remarkable thermal efficiency that surpasses industry standards.Furthermore, [Company Name] ensures that the manufacturing process adheres to stringent quality control measures. Rigorous tests and inspections are conducted at various stages, ensuring that each brick meets the highest quality standards. This meticulous attention to detail guarantees that customers receive a reliable, power-saving, and durable insulation solution that meets their specific requirements.The high alumina insulation bricks offered by [Company Name] are available in a range of sizes and shapes, making them suitable for various construction applications. Whether it's the construction of furnaces, stoves, kilns, or any other high-temperature environment, these bricks exhibit exceptional performance and resistance to thermal shock.Additionally, [Company Name] prides itself on its commitment to sustainable practices. The manufacturing process for the high alumina insulation bricks is designed to minimize waste and reduce environmental impact. By utilizing advanced technology and efficient recycling methods, the company ensures that its operations are conducted with minimal carbon footprints, promoting a healthier and greener planet.[Company Name] has a rich history in the brick manufacturing industry, boasting years of experience and expertise. With a team of skilled professionals and cutting-edge facilities, the company has consistently delivered products of exceptional quality and performance. The introduction of high alumina insulation bricks further cements their position as an industry leader and their dedication to innovation.As the demand for energy-efficient and sustainable construction materials grows, [Company Name] remains at the forefront of the industry, continually striving to provide groundbreaking solutions. The high alumina insulation bricks are a testament to their dedication to customer satisfaction and their commitment to shaping the future of the construction industry.About [Company Name]:[Company Name] is a renowned brick manufacturing company with years of experience in the industry. Known for their commitment to quality and innovation, they consistently deliver products that exceed customer expectations. With a focus on energy efficiency and sustainability, [Company Name] aims to revolutionize the construction industry with their exceptional high alumina insulation bricks.For media inquiries, please contact:[Contact Name][Company Name][Phone Number][Email Address]

Understanding the Importance of Arc Furnace Electrodes for Industrial Applications

The company has been a leading producer of high-quality arc furnace electrodes for many years. Their electrodes are used in electric arc furnaces to melt scrap steel and produce high-quality steel products.The company has a long history of providing reliable and efficient electrode solutions to their customers. With a strong focus on research and development, they have continuously improved their electrode products to meet the evolving needs of the steel industry.Their electrodes are made from high-quality raw materials and are manufactured using state-of-the-art production techniques. This ensures that their electrodes have excellent conductivity, high thermal resistance, and superior mechanical strength, making them ideal for use in electric arc furnaces.In addition to producing standard electrodes, the company also offers custom electrode solutions to meet the specific needs of their customers. They work closely with their clients to understand their requirements and develop tailored electrode solutions that optimize the performance of their electric arc furnaces.The company's commitment to quality and innovation has earned them a strong reputation in the industry. They are known for their reliable products, excellent customer service, and their ability to deliver electrode solutions that enhance the efficiency and productivity of electric arc furnaces.As a socially responsible company, they are also committed to sustainability and environmental protection. They prioritize the use of environmentally friendly production processes and materials, and they adhere to strict environmental standards in all aspects of their business operations.Their dedication to quality, innovation, and sustainability has made them a trusted partner for steel manufacturers around the world. Whether it's for large-scale steel production or specialized steel products, the company's electrodes are the go-to choice for many steel producers.Furthermore, the company's technical support team is highly knowledgeable and experienced, and they work closely with their customers to provide assistance and guidance throughout the electrode selection and implementation process. This ensures that their customers are able to maximize the performance of their electric arc furnaces and achieve their production goals.Looking ahead, the company is committed to continued innovation and the development of cutting-edge electrode solutions. They are continuously investing in research and development to stay ahead of industry trends and provide their customers with the most advanced electrode products on the market.In summary, the company is a leading producer of arc furnace electrodes, known for their high-quality products, innovative solutions, and commitment to sustainability. With their expertise and dedication to customer satisfaction, they are well-positioned to remain a key player in the global steel industry for many years to come.

High-Quality Castable Cement for Sale

[Company Name], a leading manufacturer of construction materials, has recently launched a new product in their line of castable cement. This new castable cement is expected to revolutionize the construction industry with its innovative technology and superior performance.The new castable cement is designed to offer exceptional strength, durability, and workability, making it ideal for a wide range of applications in the construction industry. It is formulated with high-quality materials that provide excellent bonding and adhesion, ensuring long-lasting and reliable results.One of the key features of this new castable cement is its high heat resistance, making it suitable for use in high-temperature environments such as kilns, furnaces, and industrial chimneys. This makes it a preferred choice for industries that require reliable and durable materials for their operations."We are excited to introduce this new castable cement to the market," said the spokesperson for [Company Name]. "We have conducted extensive research and development to ensure that this product meets the highest standards of quality and performance. We believe that it will set a new benchmark for castable cement in the industry."In addition to its exceptional strength and heat resistance, the new castable cement also offers excellent workability, allowing for easy mixing, pouring, and shaping. This makes it a versatile and user-friendly option for construction professionals, enabling them to achieve precise and reliable results in their projects.The company has also highlighted the environmental sustainability of the new castable cement, emphasizing its low carbon footprint and eco-friendly formulation. This is in line with [Company Name]'s commitment to responsible and sustainable manufacturing practices, ensuring that their products have minimal impact on the environment."We are dedicated to producing construction materials that not only deliver superior performance but also prioritize environmental responsibility," the spokesperson added. "With our new castable cement, customers can trust that they are choosing a product that aligns with their sustainability goals."[Company Name] has already received positive feedback from early users and industry professionals who have tested the new castable cement. Many have commended its exceptional performance and reliability, citing it as a game-changer in the construction materials market.To support the launch of the new product, [Company Name] has also rolled out a comprehensive marketing and distribution strategy, ensuring that the new castable cement is readily available to customers across the market. This includes partnerships with leading retailers and distributors, as well as targeted promotional campaigns to raise awareness and drive demand for the new product.With the introduction of this new castable cement, [Company Name] aims to further solidify its position as a leader in the construction materials industry. The company's commitment to innovation, quality, and sustainability has positioned it as a trusted partner for construction professionals, and the new castable cement is a testament to their dedication to delivering cutting-edge solutions.As the construction industry continues to evolve and demand for high-performance materials grows, [Company Name] remains at the forefront, driving innovation and setting new standards for quality and performance. The launch of the new castable cement is a reflection of their ongoing commitment to excellence and their vision for a more sustainable and advanced construction industry.

The latest developments in refractory casting techniques and applications

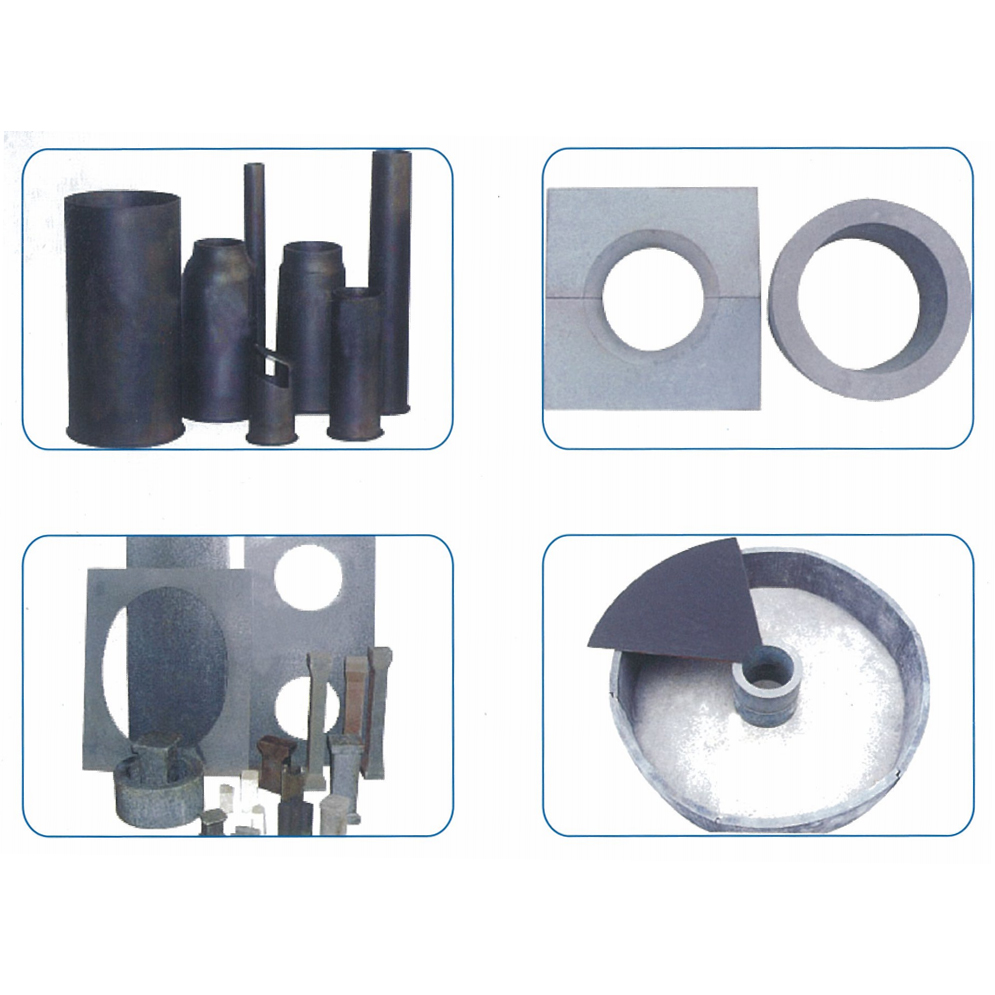

Refractory casting is an essential process in the manufacturing industry, playing a crucial role in the production of various products such as steel, glass, ceramics, and cement. The process involves pouring a liquid material, usually a mixture of refractory material and binding agents, into a mold to create a specific shape that can withstand high temperatures and harsh environments. This process is fundamental in the development of industrial products and plays a critical role in the overall manufacturing process.{Company Name} is a leading provider of refractory casting services, with a strong reputation for delivering high-quality and reliable solutions to its clients. The company specializes in providing custom refractory casting solutions for a wide range of industries, including steelmaking, glass manufacturing, foundries, and more. With a team of experienced professionals and state-of-the-art facilities, {Company Name} has earned a reputation for excellence and innovation in the field of refractory casting.One of the key factors that set {Company Name} apart from its competitors is its commitment to using the latest technologies and materials to create superior refractory casting solutions. The company invests heavily in research and development to ensure that its clients receive the most advanced and effective products on the market. This dedication to innovation allows {Company Name} to stay ahead of industry trends and continue to provide cutting-edge solutions to its clients.In addition to its focus on innovation, {Company Name} is also known for its dedication to customer satisfaction. The company works closely with its clients to understand their specific needs and requirements, providing tailored solutions that meet and exceed expectations. Whether it's creating custom molds for unique shapes or developing specialized refractory materials for specific applications, {Company Name} is committed to delivering superior results for its clients.Furthermore, {Company Name} prides itself on its commitment to sustainability and environmental responsibility. The company actively seeks out eco-friendly materials and processes to minimize its impact on the environment. By prioritizing sustainability, {Company Name} not only benefits the planet but also provides its clients with responsible and ethically-sourced refractory casting solutions.In recent news, {Company Name} has announced the launch of a new and improved refractory casting process. This updated process incorporates the latest advancements in materials and technology to provide even better performance and longevity for industrial applications. By continually evolving and refining its casting process, {Company Name} aims to maintain its position as a leader in the industry and continue to meet the evolving needs of its clients.The new and improved casting process offers enhanced durability and resistance to high temperatures, making it an ideal choice for demanding industrial applications. With this development, {Company Name} once again demonstrates its dedication to providing top-of-the-line solutions for its clients and solidifying its reputation as an industry leader in refractory casting.{Company Name} is excited to introduce this enhanced casting process to its clients, as it represents a significant step forward in the company's commitment to excellence and innovation. With this new development, {Company Name} aims to set new standards for refractory casting and continue to meet the evolving needs of the manufacturing industry.As {Company Name} continues to push the boundaries of what's possible in refractory casting, clients can expect to receive even more advanced and efficient solutions for their manufacturing needs. This commitment to innovation and performance solidifies {Company Name}'s position as a reliable and industry-leading provider of refractory casting solutions. With its dedication to sustainability, customer satisfaction, and continuous improvement, {Company Name} is well-positioned to continue its success and provide exceptional casting solutions for years to come.

Durable Acid Proof Brick for Industrial Applications - A Complete Guide

Acid Proof Brick, the leading manufacturer of acid-resistant bricks, has established itself as a trusted and reliable provider of high-quality products for various industries. With a strong focus on innovation and customer satisfaction, the company has continuously pushed the boundaries of technology to deliver top-notch solutions for acid-resistant applications.The company has been in the business for over 30 years, serving a wide range of clients in industries such as petrochemical, pharmaceutical, and chemical processing. Its acid-resistant bricks have been widely used in the construction of storage tanks, reaction vessels, floors, and other structures that are exposed to corrosive chemicals.One of the key factors that sets Acid Proof Brick apart from its competitors is its commitment to research and development. The company has heavily invested in state-of-the-art facilities and equipment to conduct extensive testing and quality control measures to ensure that its products meet the highest standards. This dedication to innovation has led to the development of advanced formulations and manufacturing techniques that have set new benchmarks in acid-resistant materials.In addition to its cutting-edge manufacturing capabilities, Acid Proof Brick takes pride in its team of experts who are highly knowledgeable and experienced in the field of acid-resistant materials. The company's technical staff is readily available to provide valuable insights and recommendations for clients, helping them select the most suitable products for their specific needs.Furthermore, Acid Proof Brick places a strong emphasis on environmental sustainability and safety. The company adheres to strict environmental regulations and guidelines in its manufacturing processes, ensuring that its products are safe for workers and the surrounding ecosystem. This commitment to sustainability has resonated well with environmentally conscious clients who prioritize eco-friendly solutions.Acid Proof Brick's product line includes a variety of acid-resistant bricks that are designed to withstand a wide range of corrosive substances, including sulfuric acid, hydrochloric acid, and nitric acid, among others. These bricks are engineered to provide exceptional chemical resistance, high strength, and durability, making them an ideal choice for demanding industrial applications.Moreover, Acid Proof Brick offers customization options to cater to unique project requirements. The company's flexible manufacturing capabilities enable it to produce tailor-made solutions that meet specific size, shape, and performance specifications, allowing clients to achieve optimal results for their projects.As a testament to its commitment to quality and excellence, Acid Proof Brick has obtained various certifications and accreditations from reputable organizations within the industry. This includes ISO 9001 certification, which demonstrates the company's adherence to stringent quality management practices.The company's unwavering dedication to customer satisfaction is evident in its comprehensive after-sales support and technical assistance. Acid Proof Brick goes the extra mile to ensure that its clients receive the necessary guidance and support to effectively install and maintain its acid-resistant products, thereby maximizing their longevity and performance.In conclusion, Acid Proof Brick has solidified its position as a premier provider of acid-resistant bricks, delivering innovative solutions that cater to the diverse needs of its clients. With a strong emphasis on research and development, technical expertise, environmental sustainability, and customer support, the company continues to raise the bar in the industry and remains the go-to choice for high-quality acid-resistant materials.

Discover the Benefits of High Alumina Bricks for Industrial Applications

High Alumina Bricks: A New Era of Durability and PerformanceIn the ever-evolving world of construction materials, High Alumina Bricks have emerged as a game-changer. Renowned for their exceptional durability and performance, these bricks are revolutionizing the way we approach industrial applications. One company leading the charge is {Company Name}, a pioneering manufacturer in the field. With their cutting-edge technology and unwavering commitment to quality, they are setting new industry standards and elevating the construction landscape to new heights.At its core, High Alumina Bricks are composed of high-purity alumina, a premium raw material renowned for its excellent refractory properties. These bricks are designed to withstand high temperatures, making them ideal for use in industries such as steel, cement, glass, and petrochemicals, where extreme heat is a constant challenge. Their ability to resist thermal spalling, corrosion, and thermal shock sets them apart from traditional refractory bricks, allowing for longer service life and reduced maintenance costs.{Company Name} has invested heavily in research and development, resulting in a state-of-the-art manufacturing process that produces High Alumina Bricks with unmatched quality and consistency. By utilizing advanced hydraulic presses and precision temperature control, they ensure that every brick adheres to the highest industry standards. These carefully curated manufacturing techniques guarantee high mechanical strength, low shrinkage, and excellent thermal stability, even under the harshest operating conditions.One of the most remarkable features of High Alumina Bricks is their ability to retain their strength and integrity at elevated temperatures. With a high melting point, these bricks can withstand temperatures of up to 1800°C, making them a reliable choice for industries operating in extreme environments. This unique characteristic enables safer and more efficient processes, reducing downtime and increasing productivity. High Alumina Bricks act as a barrier against heat transfer, minimizing energy losses and contributing to overall cost savings for industrial operations.{Company Name}, with its cutting-edge technology and emphasis on sustainability, has also refined the production of High Alumina Bricks with a reduced environmental footprint. By implementing energy-efficient systems and utilizing raw materials from sustainable sources, they have successfully lowered greenhouse gas emissions and minimized waste generation. Their commitment to environmental stewardship is in line with the growing global demand for eco-conscious construction materials.The many advantages of High Alumina Bricks have led to their increased adoption across various industries. In the steel manufacturing sector, these bricks are widely utilized in blast furnaces, hot blast stoves, and other high-temperature areas. In the cement industry, High Alumina Bricks have become crucial components of rotary kilns and preheating zones. Additionally, glass manufacturers rely on these bricks for their excellent resistance to molten glass corrosion. The oil and gas industry has also embraced High Alumina Bricks for lining fluid catalytic cracking units and other high-temperature vessels.With ongoing advancements in technology, the future of High Alumina Bricks looks even more promising. Researchers are exploring innovative ways to enhance the thermal insulation properties of these bricks, further maximizing their efficiency and reducing energy consumption. As industries strive for increased productivity and sustainability, High Alumina Bricks are set to play a pivotal role in transforming industrial processes.In conclusion, High Alumina Bricks have emerged as a game-changer in the construction materials industry, combining exceptional durability, unmatched performance, and sustainability. {Company Name}'s commitment to innovation and superior quality has positioned them as a leader in this field. As industries continue to seek reliable solutions for their high-temperature challenges, High Alumina Bricks will undoubtedly pave the way for a new era of durability and performance.

Durable and Heat-Resistant Castable Refractory: What You Need to Know

Castable Refractory is a high-quality, heat-resistant material used in various industrial applications such as furnaces, kilns, incinerators, and reactors. It is a key component for maintaining the structural integrity of these equipment in high-temperature environments.{Company Name} has been a leading producer of Castable Refractory for over 50 years. With a strong focus on research and development, {Company Name} has continuously innovated and improved its products to meet the ever-changing demands of the industry. Its Castable Refractory products are known for their outstanding performance, durability, and reliability, making them the top choice for many businesses in the manufacturing, petrochemical, and energy sectors.The company prides itself on its state-of-the-art manufacturing facilities that utilize the latest technology and production processes to ensure the highest quality of its Castable Refractory products. Its team of experienced engineers and technicians are dedicated to maintaining strict quality control measures throughout the production process, from raw material selection to final product testing. This commitment to quality has earned {Company Name} a strong reputation as a trusted supplier of Castable Refractory solutions.In addition to its high-quality products, {Company Name} also offers comprehensive technical support and consulting services to help its customers select the right Castable Refractory for their specific application. Its team of experts can provide on-site assessments, recommend customized solutions, and offer guidance on installation and maintenance to ensure optimal performance and longevity of the refractory lining.One of the key factors that set {Company Name} apart from its competitors is its focus on sustainability and environmental responsibility. The company is committed to reducing its environmental impact by implementing eco-friendly manufacturing practices and developing innovative refractory materials that are energy-efficient and reduce emissions. This dedication to sustainability has not only earned {Company Name} the trust of its customers but also positioned it as a leader in responsible refractory production.{Company Name} has a global presence, serving customers in various industries across the world. Its network of distributors and sales representatives ensures that its high-quality Castable Refractory products and services are readily available to businesses in need of reliable refractory solutions. With a strong emphasis on customer satisfaction, {Company Name} strives to build long-lasting partnerships and provide ongoing support to its clients to meet their evolving needs.Looking ahead, {Company Name} is committed to furthering its position as a leading supplier of Castable Refractory by continuing to invest in research and development, expanding its product offerings, and adapting to the changing needs of the industry. The company remains dedicated to providing the highest quality products and services, while maintaining its commitment to sustainability and environmental responsibility.In conclusion, {Company Name} is a trusted and reputable source for high-quality Castable Refractory solutions. With its commitment to innovation, quality, sustainability, and customer satisfaction, the company is well-positioned to meet the growing demand for reliable refractory materials in various industrial applications.