Durable and High-Quality Fire Kiln Refractory Bricks for Sale

By:Admin

In the world of high-temperature industrial processes, having the right refractory materials is essential. With the advancement of technology and the increasing demand for high performance in various industries, the need for reliable and durable refractory bricks has become more critical than ever. This is where Fire Kiln Refractory Bricks come into play.

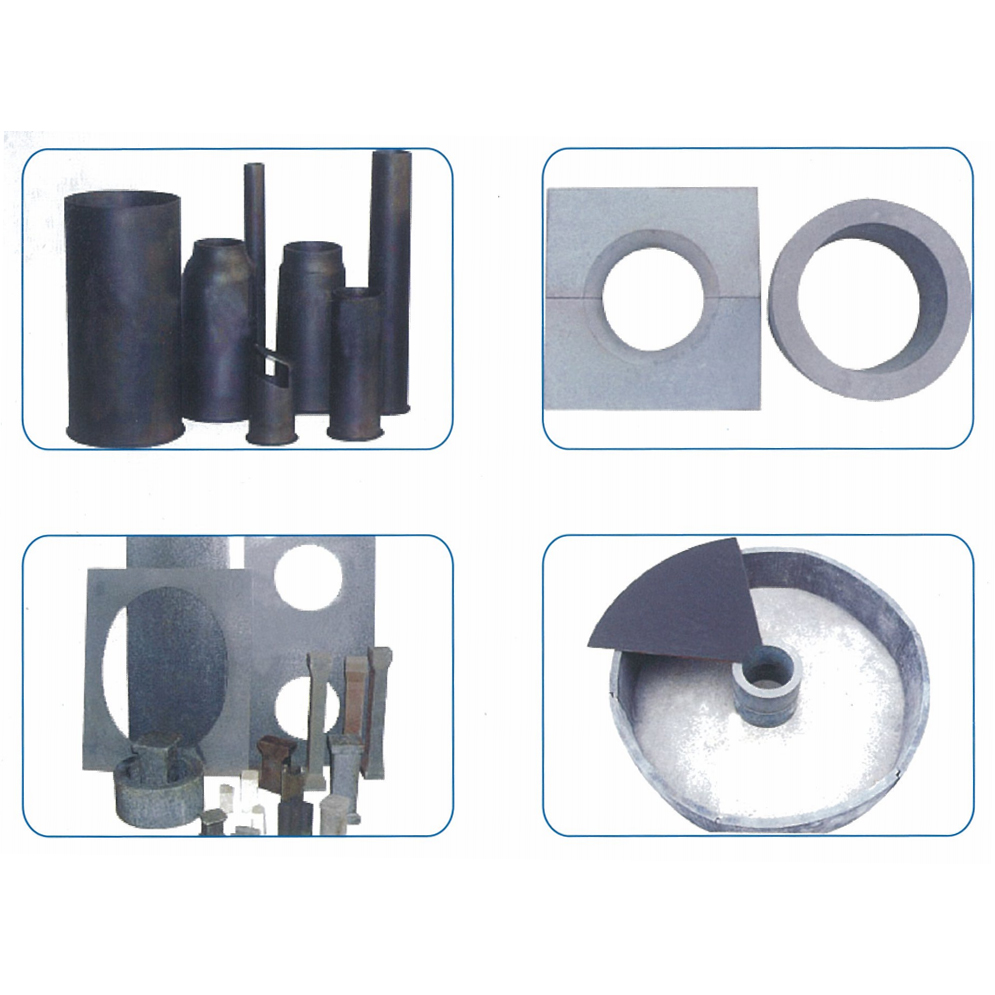

Fire Kiln Refractory Bricks, offered by a leading refractory materials manufacturer, are designed to withstand extreme temperatures and harsh conditions. These bricks are used in a wide range of applications, including in the construction of furnaces, kilns, and other high-temperature equipment in industries such as steel, cement, glass, and petrochemicals.

The company behind Fire Kiln Refractory Bricks has a long-standing reputation for producing high-quality refractory materials. With decades of experience in the industry, they have gained a deep understanding of the unique requirements of different industrial processes and have developed a comprehensive range of refractory solutions to meet these demands.

The Fire Kiln Refractory Bricks are made from high-quality raw materials, carefully selected to ensure optimal performance and durability. These materials are processed using advanced manufacturing techniques to create bricks that offer exceptional resistance to thermal shock, abrasion, and chemical corrosion. This makes them the ideal choice for applications where high temperatures and harsh environments are the norm.

One of the key features of Fire Kiln Refractory Bricks is their excellent thermal insulating properties. This allows them to effectively retain heat within the equipment, resulting in improved energy efficiency and reduced operating costs for industrial facilities. Additionally, their high mechanical strength and low porosity make them capable of withstanding the rigorous conditions of high-temperature processes, ensuring a longer service life and minimal downtime for maintenance.

The company also offers customizable solutions to meet the specific needs of different industries and applications. Whether it's a specific shape, size, or composition requirement, they can tailor their Fire Kiln Refractory Bricks to deliver the best performance and longevity for their customers' equipment.

Furthermore, the company places a strong emphasis on sustainability and environmental responsibility in the production of Fire Kiln Refractory Bricks. By using eco-friendly raw materials and energy-efficient manufacturing processes, they minimize the environmental impact of their operations while ensuring that their products meet the highest quality and performance standards.

To support their customers in getting the most out of their Fire Kiln Refractory Bricks, the company also provides technical support and expertise. Their team of experienced engineers and technicians can offer guidance on the selection, installation, and maintenance of refractory materials, helping their customers optimize the performance and longevity of their equipment.

In conclusion, Fire Kiln Refractory Bricks are a testament to the commitment of the company to providing high-quality, reliable, and sustainable refractory solutions for high-temperature industrial applications. With their exceptional performance, durability, and customizable options, these bricks are the ultimate choice for industries that rely on efficient and reliable high-temperature equipment. Whether it's for the construction of new facilities or the maintenance of existing ones, Fire Kiln Refractory Bricks offer the assurance of superior performance and longevity, making them the go-to solution for industrial processes operating at extreme temperatures.

Company News & Blog

Durable High Temperature Castable Refractory for Industrial Use

[Company Name], a leading manufacturer and supplier of high-quality refractory products, has recently introduced a new high temperature castable refractory to meet the growing demand in the global market. The new product is designed to withstand extreme temperatures and harsh conditions, making it an ideal choice for various industrial applications.The high temperature castable refractory is a versatile and cost-effective solution for industries such as steel, cement, petrochemical, and power generation. It is specially formulated to provide excellent thermal insulation, resistance to thermal shock, and superior strength at elevated temperatures. This makes it suitable for use in furnaces, boilers, incinerators, and kilns, where extreme heat and chemical exposure can cause significant damage to traditional refractory materials.The new product is part of [Company Name]'s commitment to innovation and continuous improvement in refractory technology. With a team of experienced engineers and technicians, the company has developed a superior formulation that offers exceptional performance and durability in high temperature environments. By leveraging advanced manufacturing processes and stringent quality control measures, they ensure that the high temperature castable refractory meets the highest industry standards and customer expectations.In addition to its exceptional performance, the high temperature castable refractory also offers ease of installation and maintenance, making it a preferred choice for industrial facilities looking to optimize their operational efficiency. Its excellent flowability and self-leveling properties allow for seamless application, while its durability and resistance to abrasion and erosion ensure long-term reliability and cost savings for end users.[Company Name] is also known for its unmatched technical support and customer service. They offer comprehensive consultation and on-site assistance to help customers select the most suitable refractory products for their specific needs and provide guidance on installation, maintenance, and troubleshooting. Their commitment to customer satisfaction and long-term partnerships has earned them a reputation as a trusted and reliable supplier of refractory solutions worldwide.The launch of the new high temperature castable refractory aligns with [Company Name]'s strategic vision to expand its product portfolio and reach new markets. With a strong focus on research and development, they continue to invest in cutting-edge technologies and advanced materials to address the evolving needs of the industry. By collaborating with customers and industry partners, they are able to anticipate market trends and develop innovative solutions that deliver superior performance and value.As a socially responsible company, [Company Name] also prioritizes sustainability and environmental stewardship in its operations. The high temperature castable refractory is manufactured using eco-friendly processes and materials, minimizing its carbon footprint and environmental impact. This reflects the company's commitment to sustainable practices and its role in contributing to a greener and more sustainable future for the industry and the planet.Overall, [Company Name]'s new high temperature castable refractory sets a new standard for performance and reliability in high temperature applications. With its exceptional properties, ease of use, and industry-leading technical support, it is poised to make a significant impact in the global refractory market and deliver unparalleled value to customers across diverse industries. As the company continues to drive innovation and excellence in refractory technology, it remains a trusted partner for businesses seeking superior solutions for their high temperature challenges.

High-Quality Alumina Hollow Refractory Brick for Industrial Applications

[The company] is proud to introduce its latest innovative product, the Alumina Hollow Refractory Brick. This new addition to our existing line of refractory products is designed to meet the demands of high-temperature industrial processes, offering superior performance and durability.The Alumina Hollow Refractory Brick is made from high-quality alumina and other raw materials, carefully selected to ensure the highest level of thermal insulation and resistance to chemical corrosion. Its unique hollow design further enhances its insulation properties, making it an ideal choice for applications that require efficient heat retention and energy savings.One of the key benefits of the Alumina Hollow Refractory Brick is its exceptional strength and stability at elevated temperatures. This makes it an excellent choice for lining kilns, furnaces, and other equipment used in the production of iron, steel, cement, and other high-temperature materials. Its ability to withstand extreme conditions without sacrificing its structural integrity ensures long-term reliability and cost-effectiveness for our customers.In addition to its superior thermal properties, the Alumina Hollow Refractory Brick also offers excellent resistance to thermal shock and mechanical wear. This extends its service life and reduces maintenance requirements, resulting in lower operating costs and increased productivity for industrial facilities.Furthermore, the Alumina Hollow Refractory Brick is available in a variety of shapes and sizes to suit different application requirements. Our team of experts can work closely with customers to provide customized solutions that meet their specific needs, ensuring optimal performance and efficiency.At [the company], we are committed to delivering high-quality refractory products that exceed our customers' expectations. The development of the Alumina Hollow Refractory Brick is a testament to our dedication to innovation and continuous improvement. We strive to stay ahead of industry trends and technological advancements, offering solutions that help our customers stay competitive in today's challenging business environment.In the field of refractory materials, our company has established a strong reputation for excellence, driven by our relentless pursuit of quality and reliability. The introduction of the Alumina Hollow Refractory Brick further solidifies our position as a leading provider of advanced refractory solutions, trusted by numerous industries worldwide.As part of our commitment to sustainability and environmental responsibility, the Alumina Hollow Refractory Brick is manufactured using eco-friendly processes and raw materials. This aligns with our company's values of contributing to a cleaner and greener future for the planet, while also ensuring the health and safety of our employees and the communities in which we operate.In conclusion, the introduction of the Alumina Hollow Refractory Brick marks another milestone in our journey to provide the best refractory solutions to our customers. With its unmatched thermal insulation, resistance to corrosion, and long-lasting performance, this innovative product reflects our dedication to excellence and our vision for a more efficient and sustainable industrial sector. We look forward to serving our customers with this new addition to our product line, and we remain committed to driving progress and success in the industries we serve.

Discover the Latest Advancements in Fire Kiln Refractory Bricks

Fire Kiln Refractory Bricks Continue to Revolutionize the Construction IndustryFire Kiln Refractory Bricks (name removed), a leading manufacturer and supplier of high-quality refractory bricks, has been making waves in the construction industry with its innovative and durable products. These refractory bricks have proven to be a game-changer, offering unparalleled strength and longevity for various applications, including kilns, furnaces, and fireplaces. With a strong commitment to research and development, (name removed) has been able to continuously introduce cutting-edge products, contributing to the growth and advancement of the industry.Refractory bricks are specially designed to withstand high temperatures and harsh conditions, making them essential components in industries that involve extreme heat. Traditional bricks are not suitable for these environments, as they tend to crack, warp, or break under intense heat. In contrast, (name removed)'s fire kiln refractory bricks are manufactured using the highest quality raw materials and advanced techniques, resulting in an incredibly durable product that can withstand temperatures of up to 1800 degrees Celsius.One of the key factors that sets (name removed) apart from its competitors is its commitment to continuous improvement through research and development. The company invests heavily in technology and innovation, ensuring that its products are always at the forefront of the industry. By collaborating with experts and industry professionals, (name removed) is able to identify emerging trends and develop novel solutions to address the unique challenges faced by its customers.(name removed)'s fire kiln refractory bricks come in a variety of shapes, sizes, and compositions to meet the diverse needs of its customers. Whether it's a large industrial furnace or a small backyard fireplace, (name removed) can provide the perfect refractory bricks to ensure optimal performance and longevity. The company also offers customized solutions, working closely with clients to design and manufacture bricks that meet their specific requirements.In addition to their remarkable durability, (name removed)'s refractory bricks offer superior insulation properties, contributing to energy efficiency and cost savings. By minimizing heat loss, these bricks help to maintain stable temperatures and reduce energy consumption, thus increasing the overall efficiency of the system. This not only benefits the environment but also saves the end-users substantial amounts of money in the long run.Furthermore, (name removed) places great emphasis on sustainability and environmental responsibility throughout its manufacturing processes. By using environmentally friendly materials and adopting eco-friendly practices, they strive to minimize their carbon footprint and contribute to a greener future. The company also adheres to strict quality control measures to ensure that its products consistently meet or exceed industry standards.Since its inception, (name removed) has quickly established itself as a trusted and reliable supplier of refractory bricks. Its commitment to excellence, customer satisfaction, and continuous innovation has earned the company a solid reputation in the industry. With a global presence and a vast network of distribution partners, (name removed) is well-equipped to serve clients from various sectors and regions.In conclusion, the innovative fire kiln refractory bricks manufactured by (name removed) have revolutionized the construction industry. These durable and heat-resistant bricks have become the go-to choice for industries that require materials capable of withstanding extreme temperatures. With a focus on research and development, (name removed) continues to introduce cutting-edge solutions, pushing the boundaries of what is possible in the field of refractory brick manufacturing. As the company grows and expands its product offerings, it is poised to play a pivotal role in shaping the future of the industry.

Durable High Alumina Refractory Bricks: A Key Construction Material

High Alumina Refractory Bricks, also known as Alumina-Silicate Fire Bricks, are made from high-alumina bauxite or clay, and are widely used in various industrial applications such as lining of furnaces, kilns, and reactors. They are known for their high temperature resistance, low thermal conductivity, and excellent thermal shock resistance, making them an essential component in many industrial processes.One leading manufacturer and supplier of High Alumina Refractory Bricks is [Company Name]. [Company Name] has been a pioneer in the field of manufacturing and supplying refractory products for over [X] years. The company takes pride in its state-of-the-art manufacturing facilities, advanced technology, and a team of skilled professionals who are dedicated to delivering high-quality products that meet the stringent requirements of their clients.[Company Name] offers a wide range of High Alumina Refractory Bricks, which are designed to withstand high temperatures and harsh environments. Their products are known for their superior strength, abrasion resistance, and long service life. The company's High Alumina Refractory Bricks are extensively used in the steel, cement, glass, and petrochemical industries, among others.One of the key advantages of [Company Name]'s High Alumina Refractory Bricks is their ability to maintain their physical and chemical properties at elevated temperatures, making them ideal for applications where thermal insulation and resistance to thermal shock are critical. The company's products are also known for their high refractoriness, meaning they can withstand extreme heat without losing their shape or strength.In addition to their excellent thermal properties, [Company Name]'s High Alumina Refractory Bricks also offer high chemical resistance, making them suitable for use in environments with corrosive substances or high alkali content. This makes them a preferred choice for lining equipment and structures in industries where harsh chemicals are used.Another key feature of [Company Name]'s High Alumina Refractory Bricks is their low porosity, which prevents the penetration of liquids and gases, making them ideal for applications where containment and insulation are crucial. This property also ensures that the bricks have minimal shrinkage at high temperatures, leading to a longer service life and reduced maintenance costs for their clients.The manufacturing process of [Company Name]'s High Alumina Refractory Bricks involves the use of high-quality raw materials and stringent quality control measures to ensure that the final product meets the highest standards. The company's dedication to quality and innovation has earned them a reputation for reliability and excellence in the industry.Furthermore, [Company Name] has a strong focus on research and development, constantly striving to enhance the performance and properties of their High Alumina Refractory Bricks. This commitment to innovation allows them to stay ahead of the competition and offer their clients the most advanced and effective refractory solutions available in the market.In conclusion, [Company Name] is a leading manufacturer and supplier of High Alumina Refractory Bricks, offering a comprehensive range of products that are designed to meet the diverse needs of their clients. With a strong emphasis on quality, innovation, and customer satisfaction, [Company Name] continues to be a trusted partner for industries that rely on high-performance refractory materials for their critical processes.

Exceptional Quality Magnesia Carbon Brick for a Better Ladle Performance

Magnesia Carbon Brick for Ladle: A Revolutionary Solution for High-Temperature ApplicationsIn the ever-evolving field of refractories, a remarkable development has taken place with the introduction of Magnesia Carbon Brick for Ladle. This groundbreaking product has emerged as a game-changer in high-temperature applications, offering unparalleled performance and durability. With its unique composition and superior properties, this advanced refractory material ensures optimal performance in various industrial processes.Before delving into the specifics of this groundbreaking innovation, let us acquaint ourselves with the company behind this remarkable product. Founded several decades ago, this refractory manufacturer has been at the forefront of delivering cutting-edge solutions to industries worldwide. Known for their commitment to research and development, the company has garnered a reputation for producing best-in-class materials that cater to the most demanding customer requirements.Magnesia Carbon Brick for Ladle, the latest addition to their extensive product portfolio, is engineered to withstand extreme conditions encountered in ladle applications. Ladles are indispensable tools in the steel and metallurgy industries, used for transporting and pouring molten metal. Given the harsh and corrosive nature of these processes, the linings of ladles are subjected to extreme temperatures, chemical reactions, and mechanical stress.Traditionally, bricks made of magnesia and carbon have been used in ladle linings due to their excellent resistance to high temperatures. However, these conventional bricks have limitations such as high oxidation rates, poor thermal shock resistance, and susceptibility to carbon pickup. Recognizing the need for a more robust and reliable solution, our innovators have developed the Magnesia Carbon Brick for Ladle.This advanced refractory material features a unique combination of magnesia, graphite, and various additives, resulting in a high-performance composite with exceptional properties. The addition of graphite enhances the material's thermal shock resistance and provides increased resistance to slag penetration, while the carefully selected additives improve the overall mechanical strength and oxidation resistance.The Magnesia Carbon Brick for Ladle offers several notable advantages over its predecessors. The improved oxidation resistance significantly extends the service life of the lining, reducing downtime and maintenance costs. Moreover, the enhanced thermal shock resistance ensures reliable performance even in rapid temperature fluctuations, minimizing the risk of premature failure.Another key aspect of this revolutionary product is its excellent resistance to carbon pickup. Carbon pickup refers to the absorption of carbon by molten metal, resulting in the formation of carbides and compromising the quality of the final product. By mitigating this issue, the Magnesia Carbon Brick for Ladle ensures the production of high-quality steel with consistent properties.Furthermore, this magnesia carbon brick offers superior corrosion resistance to chemical attacks from molten metals and slags. This resistance is crucial for maintaining the integrity of the ladle lining, preventing leaks or contamination that could impact the overall process efficiency and product quality.Considering the widespread applications of ladles in the steel and metallurgy industries, the adoption of Magnesia Carbon Brick for Ladle is expected to have a significant impact. The extended service life and enhanced performance of this refractory material will help manufacturers optimize their processes, reduce production costs, and improve overall productivity.In conclusion, the introduction of Magnesia Carbon Brick for Ladle marks a significant advancement in the field of refractories. With its remarkable properties and exceptional performance, this innovative product ensures optimal performance in high-temperature applications, such as ladle linings. Developed by a renowned refractory manufacturer, this advanced material underscores their commitment to delivering cutting-edge solutions that meet the evolving needs of industries worldwide. As its adoption grows, this revolutionary brick holds the promise of revolutionizing ladle applications and contributing to the growth and efficiency of various industrial processes.

High Quality Corrosion Resistant Castable for Your Industrial Needs

Corrosion Resistant Castable: A Game-Changer in the Refractory IndustryThe refractory industry has been revolutionized with the introduction of Corrosion Resistant Castable, a cutting-edge product that promises superior performance and durability in high-temperature environments. This innovative solution has been developed by the renowned company, {}, which prides itself on its commitment to excellence and continuous innovation in the field of refractory materials.{} has been a leading player in the refractory industry for decades, leveraging its expertise and advanced manufacturing capabilities to produce high-quality refractory products that meet the most demanding requirements. The company has built a strong reputation for delivering reliable solutions to a wide range of industries, including steel, petrochemical, cement, and power generation.The introduction of Corrosion Resistant Castable marks a significant milestone for {}. This groundbreaking product is designed to address the challenges of corrosion and erosion in high-temperature environments, offering exceptional resistance to chemical attack and mechanical wear. With its unique composition and advanced properties, this castable has the potential to outperform traditional refractory materials, providing long-lasting protection in aggressive operating conditions.The key features of Corrosion Resistant Castable include high strength, excellent corrosion resistance, and thermal stability, making it an ideal choice for critical applications in industries where harsh operating conditions are a constant challenge. Whether it's in the lining of rotary kilns, incinerators, or boilers, this innovative castable demonstrates exceptional performance and reliability, ensuring optimal operational efficiency and cost savings for end-users.One of the most notable advantages of Corrosion Resistant Castable is its ability to withstand the effects of chemical attack from acids, alkalis, and other corrosive substances, which are common in many industrial processes. This superior resistance to corrosion not only extends the service life of refractory linings but also minimizes the need for frequent maintenance and repairs, reducing downtime and overall operating costs for plants and facilities.In addition to its corrosion-resistant properties, this advanced castable also offers exceptional thermal insulation, allowing for efficient heat containment and energy conservation in high-temperature applications. By minimizing heat loss and optimizing thermal efficiency, Corrosion Resistant Castable contributes to the sustainability and environmental performance of industrial operations, aligning with the growing focus on green and energy-efficient technologies.The development of Corrosion Resistant Castable is a testament to {}. Their team of experienced and dedicated researchers and engineers have invested significant resources in R&D to create a product that not only meets but exceeds industry standards. Through rigorous testing and continuous refinement, they have succeeded in developing a castable that sets a new benchmark for performance and reliability in refractory materials.As a leading supplier of refractory solutions, {} is well-equipped to support the implementation of Corrosion Resistant Castable in various industrial applications. Their extensive technical expertise and customer-centric approach enable them to provide tailored recommendations and comprehensive support to end-users, ensuring the successful deployment and optimal performance of this innovative product.The launch of Corrosion Resistant Castable has generated considerable excitement and anticipation within the refractory industry. Its potential to transform the way high-temperature processes are managed and maintained has sparked interest among plant operators, engineers, and industry professionals who are seeking advanced solutions to enhance the durability and efficiency of their operations.In conclusion, Corrosion Resistant Castable represents a significant breakthrough in the field of refractory materials, offering unparalleled resistance to corrosion, erosion, and thermal degradation. With its advanced features and proven performance, this innovative product is poised to make a lasting impact in the industry, setting new standards for quality, reliability, and longevity. With the expertise and support of {}, customers can confidently embrace this game-changing solution and unlock the full potential of their high-temperature applications.

Get High-Quality Corundum Bricks Online: Exploring Options for Premium Refractories

Title: Refractories Corundum Bricks: Revolutionizing High-Temperature ApplicationsIntroduction:When it comes to high-temperature applications in industries such as steel, cement, and glass, one key component that plays a crucial role in ensuring structural integrity and heat resistance is refractory materials. Among these materials, Corundum Bricks have emerged as a game-changer, providing exceptional durability and resistance to extreme temperatures. This article delves into the features and applications of these refractory bricks, showcasing their effectiveness in revolutionizing high-temperature industries.Section 1: Understanding Refractories Corundum BricksRefractories Corundum Bricks are advanced ceramic materials primarily made from fused alumina (Al2O3) or synthetic mullite. Their exceptional strength, chemical stability, and high-performance characteristics make them ideal for applications that involve harsh environments and extreme temperatures exceeding 1500°C. Being composed of around 90% or more alumina, Corundum Bricks possess excellent resistance to corrosion, wear, thermal shock, and creep.Section 2: Features of Corundum Bricksa) High-temperature resistance: Corundum Bricks exhibit remarkable stability even in extreme temperature conditions, ensuring integrity and longevity of structures.b) Chemical resistance: With their dense structure and low porosity, these bricks effectively resist the corrosive effects of various chemicals, alkaline substances, and slags.c) Low thermal conductivity: The low thermal conductivity of Corundum Bricks minimizes heat loss, creating an energy-efficient solution for furnace linings and other high-temperature applications.d) Superior mechanical strength: These bricks possess impressive mechanical strength, enabling them to withstand thermal stress and resulting in enhanced operational reliability.e) Good thermal shock resistance: The ability of Corundum Bricks to withstand rapid temperature fluctuations without cracking or spalling is pivotal in maintaining the integrity of furnace linings.Section 3: Applications of Corundum Bricksa) Steel industry: Corundum Bricks find extensive use in steelmaking processes, where they serve as linings in ladles, converters, blast furnaces, and other high-temperature equipment. Their exceptional resistance to molten metals and slag ensures durability in harsh steel manufacturing conditions.b) Cement industry: With the growing demand for cement, Corundum Bricks are employed in cement kilns and coolers due to their ability to withstand high temperatures, chemical erosion, and physical wear.c) Glass industry: Corundum Bricks are widely utilized in glass melting furnaces, helping to prevent glass corrosion and ensuring long service life.d) Petrochemical industry: These bricks are crucial for lining thermal cracking furnaces, reformer furnaces, and ethylene cracking furnaces, as they exhibit excellent chemical resistance to harsh petrochemical environments.e) Other applications: Corundum Bricks are also used in non-ferrous metal smelting, power plant boilers, waste incinerators, and other high-temperature processes.Section 4: The Company's ExpertiseThe company, as a leading manufacturer of Refractories Corundum Bricks, is dedicated to providing high-quality solutions to industries that rely on refractory materials. With state-of-the-art manufacturing facilities and a strong research and development team, the company ensures the production of premium Corundum Bricks that adhere to strict quality standards. By utilizing advanced technologies and thorough quality control measures, they have established themselves as a trusted supplier in the refractory industry.Conclusion:Refractories Corundum Bricks have revolutionized high-temperature applications in various industries by providing exceptional durability, resistance to extreme temperatures, and superior mechanical strength. As companies strive for increased productivity, efficiency, and longevity in their operations, the utilization of Corundum Bricks is becoming indispensable. With continuous advancements and a strong commitment to quality, these bricks are expected to shape the future of refractory materials, setting new standards for performance and reliability in high-temperature environments.

Durable High Alumina Fire Bricks for Superior Performance

High-Quality High Alumina Fire Bricks Offered by {}{}Fire bricks are a crucial component in many industrial and commercial applications where high temperatures are involved. {} is proud to offer a wide range of high-quality high alumina fire bricks that are designed to withstand extreme heat and provide excellent insulation. These fire bricks are essential for furnaces, kilns, and other high-temperature equipment, making them an indispensable product for a variety of industries.{}Established in {}, {} has been a leading manufacturer and supplier of refractory products for over {} years. The company specializes in the production of high alumina fire bricks, which are made from high-quality raw materials and undergo stringent quality control measures to ensure superior performance.The high alumina fire bricks offered by {} are designed to withstand temperatures of up to {}°C, making them suitable for a wide range of industrial applications. These bricks are known for their excellent thermal stability, high strength, and low thermal conductivity, making them an ideal choice for areas that are exposed to high temperatures.The manufacturing process at {} is state-of-the-art, utilizing the latest technology and equipment to produce fire bricks that meet the highest industry standards. The company's experienced team of engineers and technicians ensures that each brick is precision-engineered to withstand the rigors of high-temperature environments.In addition to their high-temperature resistance, {}'s high alumina fire bricks also offer exceptional corrosion and abrasion resistance, making them suitable for use in harsh industrial environments. These bricks have been widely used in industries such as steel, cement, glass, and non-ferrous metals, where they have proven to be reliable and durable.As a customer-focused company, {} is dedicated to providing exceptional service and support to its clients. The company offers customized solutions to meet specific application requirements and provides technical assistance to ensure that customers get the most out of their fire bricks. With a strong focus on quality and innovation, {} has earned a reputation for delivering superior products that consistently exceed customer expectations.{}In addition to high alumina fire bricks, {} also offers a comprehensive range of refractory products, including castables, insulating bricks, and refractory fibers. The company's diverse product line and commitment to research and development make it a one-stop solution for all refractory needs.With a strong commitment to sustainability, {} is also dedicated to environmental conservation and energy efficiency. The company employs eco-friendly manufacturing practices and continuously seeks ways to reduce its carbon footprint. By choosing {} as a supplier, customers can be assured that they are supporting a responsible and environmentally conscious company.The high-quality high alumina fire bricks offered by {} are a testament to the company's dedication to excellence and innovation. With a proven track record of delivering reliable and durable refractory products, {} continues to be a trusted partner for industries that rely on high-temperature equipment. As the company looks to the future, it remains committed to pushing the boundaries of what is possible in the refractory industry and setting new standards for quality and performance.

Durable Fire Bricks Made of Silica: A Reliable Choice for Fireproofing

Silica Fire Bricks are gaining popularity in the construction and industrial sectors for their durable and heat-resistant properties. These bricks are widely used in various applications, including furnace linings, boiler walls, and glass melting tanks. Their ability to withstand high temperatures and harsh environments makes them an ideal choice for construction and industrial projects.{Company} is a leading manufacturer of high-quality Silica Fire Bricks, offering a wide range of products to meet the diverse needs of its customers. With years of experience and a commitment to excellence, the company has established itself as a trusted provider of fire bricks for various industries.The company's Silica Fire Bricks are made from high-grade silica and other materials, ensuring superior thermal insulation and resistance to thermal shock. These bricks are designed to withstand temperatures of up to 1700°C, making them suitable for the most demanding applications. Whether it's for a steel plant, aluminum industry, or cement kiln, {Company}'s Silica Fire Bricks are engineered to deliver exceptional performance in high-temperature environments.One of the key features of {Company}'s Silica Fire Bricks is their high refractoriness, which allows them to maintain their structural integrity even at extreme temperatures. This property makes them an ideal choice for lining the walls of furnaces, boilers, and other industrial equipment that are exposed to intense heat. In addition, these bricks offer excellent thermal conductivity, ensuring efficient heat transfer and energy savings for industrial processes.{Company} takes pride in its state-of-the-art manufacturing facilities, which are equipped with advanced technologies to produce Silica Fire Bricks of the highest quality. The company's team of skilled engineers and technicians work tirelessly to ensure that each brick meets the strictest industry standards for performance and reliability. From raw material selection to the final inspection, {Company} maintains rigorous quality control measures to deliver products that exceed customer expectations.Furthermore, {Company} is dedicated to providing customized solutions to meet the specific requirements of its clients. The company's technical team collaborates closely with customers to develop tailored fire brick solutions that are tailored to their unique applications. This customer-centric approach has earned {Company} a reputation for delivering superior products and exceptional service to its clients around the world.In addition to its focus on quality and customer satisfaction, {Company} is committed to sustainability and environmental responsibility. The company adheres to strict environmental standards in its manufacturing processes, ensuring that its operations have minimal impact on the environment. Furthermore, {Company} constantly explores innovative ways to reduce energy consumption and waste generation, contributing to a greener and more sustainable future.As the demand for heat-resistant and durable materials continues to grow, {Company} remains at the forefront of the industry, providing reliable and high-performance Silica Fire Bricks to its global clientele. With a steadfast commitment to quality, innovation, and sustainability, {Company} is poised to continue its success as a leading provider of fire bricks for industrial and construction applications.In conclusion, Silica Fire Bricks from {Company} are the go-to choice for businesses seeking durable, high-quality fire bricks for their construction and industrial needs. With a focus on excellence, customization, and sustainability, {Company} has established itself as a trusted and reliable partner for customers around the world. As industries continue to evolve and demand the highest quality materials, {Company} remains at the forefront, delivering top-of-the-line Silica Fire Bricks that meet and exceed the expectations of its clientele.

Discover the Benefits of High Liquidity Refractory Castable for Enhanced Performance

High Liquidity Refractory Castable: Revolutionizing Refractory Industry Refractory materials play a crucial role in industries like steel, cement, glass, and petrochemicals. These materials are designed to withstand high temperatures, extreme pressures, and harsh chemical environments. However, not all refractory castables are created equal. Some exhibit low flowability, which can hinder their application and require extensive manpower. Enter the high liquidity refractory castable, a game-changer in the industry. One prominent player in this field, (brand name removed), has developed an innovative high liquidity refractory castable that is transforming the way industries approach refractory lining applications. This groundbreaking product offers unmatched flowability, ease of installation, and exceptional durability. Let's explore the benefits of this advanced castable and the company behind its success.The high liquidity refractory castable by (brand name removed) is made using a proprietary blend of carefully selected raw materials. These materials are finely ground and mixed with an optimized water binder system, resulting in a castable with exceptional flowability. This unique property allows for seamless installation, even in complex shapes and configurations, reducing the need for skilled labor and saving valuable time during construction.One key advantage of this castable is its versatility. It can be used for various refractory lining applications, such as furnace linings, chimneys, kilns, and ladles. Its high liquidity ensures full coverage and precise filling, minimizing gaps and weak points in the lining, which ultimately leads to improved thermal efficiency and superior performance.In addition to its exceptional flowability, the high liquidity refractory castable also exhibits exceptional durability. It has excellent resistance to thermal shocks, chemical attacks, and abrasion, making it ideal for applications exposed to extreme temperatures and corrosive environments. This durability translates into reduced maintenance costs and extended service life, resulting in significant savings for industries.The success of (brand name removed) and its high liquidity refractory castable can be attributed to the company's commitment to research and development. The brand invests heavily in state-of-the-art facilities and a team of highly skilled experts to ensure continuous innovation and improvement of their products. Their rigorous testing procedures and quality control measures ensure that every batch of castable meets the highest industry standards.Furthermore, the company's customer-centric approach sets them apart from their competitors. They work closely with their clients to understand their specific refractory requirements, provide tailored solutions, and offer technical support throughout the installation process. This approach has earned them a solid reputation and a loyal customer base.Looking ahead, (brand name removed) aims to expand its market presence globally by forming strategic partnerships and collaborations. Their goal is to make their high liquidity refractory castable widely available to industries around the world, enabling them to achieve the highest levels of efficiency and productivity.In conclusion, the introduction of high liquidity refractory castable has revolutionized the refractory industry. The innovative product developed by (brand name removed) offers unmatched flowability, ease of installation, and exceptional durability. It has the potential to significantly improve the efficiency and performance of various industries. With their commitment to research and development, along with their customer-centric approach, (brand name removed) is set to lead the refractory industry into a new era of excellence.