Different Types of Graphite Electrodes Explained

By:Admin

Introduction:

Graphite electrodes are critical components in the steelmaking and metal manufacturing industries, delivering efficient and cost-effective electrical processes. [Company name], a leading manufacturer in this field, provides a wide range of graphite electrodes that cater to diverse industry requirements. This article delves into the different types of graphite electrodes offered by [Company name], highlighting their features, applications, and benefits.

1. Regular Power (RP) Graphite Electrodes:

Regular Power (RP) graphite electrodes find extensive usage in electric arc furnaces for the production of steel. They are made from a blend of petroleum coke and pitch. RP electrodes deliver moderate electrical conductivity, making them suitable for both melting and refining processes. These electrodes are capable of withstanding high temperatures and provide stable performance.

2. High Power (HP) Graphite Electrodes:

High Power (HP) graphite electrodes from [Company name] are specifically designed for more demanding applications. With superior electrical conductivity, HP electrodes enable higher productivity and enhanced energy efficiency. These electrodes are primarily used in steelmaking through the electric arc furnace (EAF) method. Additionally, HP electrodes exhibit excellent resistance to oxidation and thermal shock, extending their service life.

3. Ultra-High Power (UHP) Graphite Electrodes:

As the name suggests, Ultra-High Power (UHP) graphite electrodes are engineered for ultra-demanding processes, achieving superior performance and efficiency. UHP electrodes offer the highest electrical conductivity and thermal properties among all graphite electrode variants. They are used in advanced steelmaking techniques such as ladle furnaces and electric arc furnaces to produce high-quality steel with exceptional purity. UHP electrodes provided by [Company name] feature enhanced durability and a longer operating life.

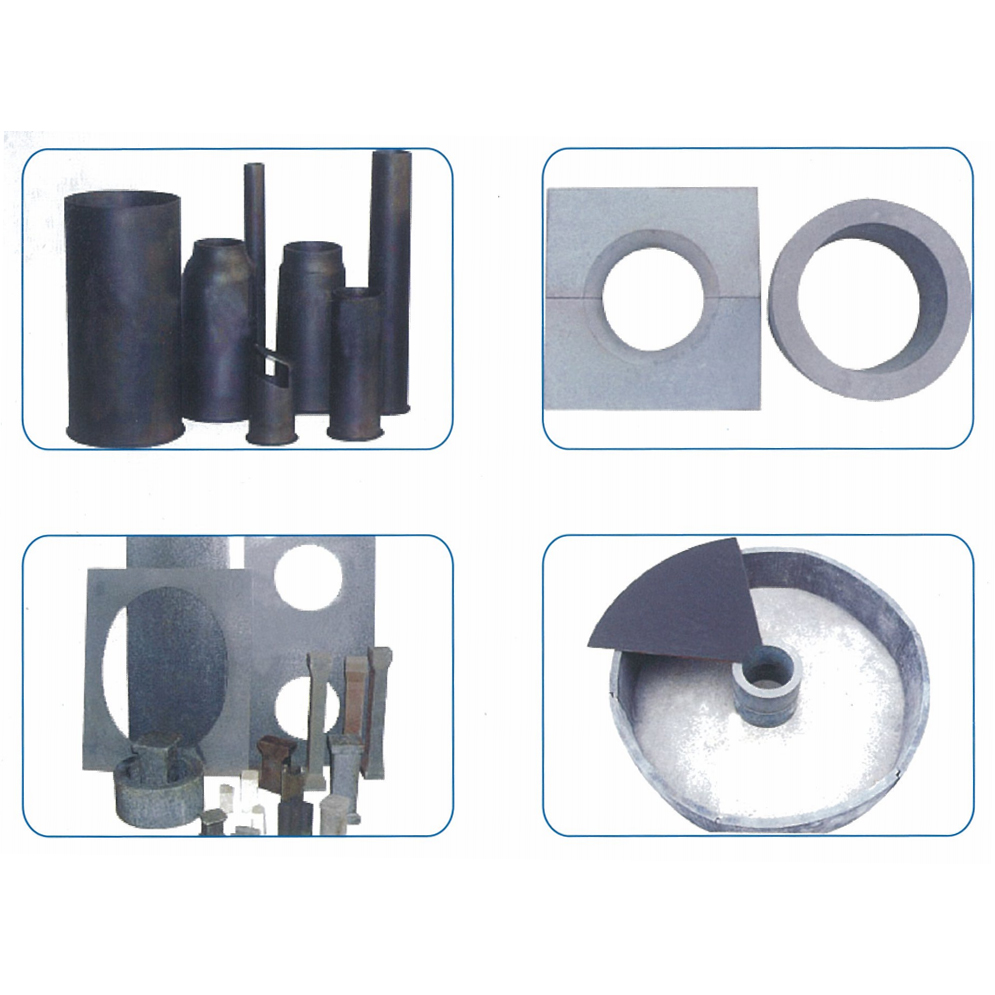

4. Special Graphite Electrodes:

Apart from the standard RP, HP, and UHP electrode categories, [Company name] provides a range of specialty graphite electrodes tailored to unique customer requirements. These specialty electrodes exhibit specific properties such as low resistivity, high flexural strength, or improved oxidation resistance. They are designed for specialized applications, including the production of non-ferrous metals like aluminum, copper, and silicon, as well as various chemical processes.

Conclusion:

[Company name] offers an extensive portfolio of graphite electrodes, including Regular Power (RP), High Power (HP), Ultra-High Power (UHP), and specialty electrodes. These electrodes cater to the diverse needs of the steelmaking and metal manufacturing industries, providing efficient and reliable electrical processes. With superior performance, longevity, and excellent thermal properties, [Company name]'s graphite electrodes serve as essential components in steel production and other specialized applications.

Note: Please replace [Company name] with the appropriate brand name when using the content.

Company News & Blog

Discover the Latest Advances in Refractory Ramming Mass for Enhanced Performance

Title: Leaders in Refractory Ramming Mass: Revolutionizing the Industrial SectorIntroduction:In today's rapidly evolving industrial landscape, companies are continuously striving to develop innovative solutions that enhance productivity, efficiency, and cost-effectiveness. One such pioneering company at the forefront of this revolution is a leading manufacturer of Refractory Ramming Mass, which has become a trusted name in the industry. With a strong commitment to quality and relentless pursuit of excellence, this company has redefined the standards of refractory materials, catering to a wide range of industrial applications. Let’s explore the incredible journey and success story of this industry leader.Industry-Leading Ramming Mass: Refractory Ramming Mass (RRM) is a high-performance refractory lining material used in various industries such as steel, mining, cement, and power plants. Recognizing the critical importance of this product in ensuring the durability and efficiency of furnaces and reactors, this manufacturer has invested heavily in research and development to create an unrivaled range of RRM. By incorporating advanced technologies and utilizing top-quality raw materials, they have produced a line of ramming mass products that outperform traditional solutions.The company has expanded its product portfolio to include a comprehensive range of RRM, catering to diverse industrial applications. Whether it is acidic, neutral, or basic refractories, this manufacturer offers tailor-made solutions that address clients' specific requirements. Their refractory materials possess exceptional characteristics such as high density, superior corrosion resistance, exceptional thermal shock resistance, and remarkable thermal conductivity. These features ensure longer service life, reduced downtime, and an overall improvement in the performance of refractory linings.Quality Assurance and Certifications:At the heart of this company's success lies an unwavering commitment to delivering uncompromising quality and reliability. The company's state-of-the-art manufacturing facilities are equipped with the latest machinery and have stringent quality control measures in place. By adhering to international standards and employing a team of highly skilled professionals, they consistently produce refractory materials that meet and exceed customer expectations.Moreover, to further solidify their credibility, the company has obtained key certifications such as ISO 9001:2015, ensuring adherence to internationally recognized quality management systems. These certifications serve as a testimony to the company's commitment to excellence and instill trust in its clientele.Research and Development:Innovation lies at the core of this manufacturer, and they continuously invest in research and development to push the boundaries of refractory technology. By partnering with renowned research institutions and collaborating with industry experts, the company stays ahead of the curve, offering cutting-edge solutions to its customers. Their relentless pursuit of innovation has led to numerous breakthroughs, making them a trendsetter in the refractory industry.Sustainability and Environmental Responsibility:In addition to striving for technological advancements, this manufacturer places great emphasis on sustainable practices and environmental responsibility. By employing eco-friendly production processes and utilizing recycled materials wherever possible, they contribute towards a greener and cleaner future. Their commitment to sustainability extends beyond their operations to assisting clients with optimizing their resource consumption, thereby minimizing their carbon footprint.Conclusion:As a global leader in the production of Refractory Ramming Mass, this company has successfully revolutionized the industrial sector with its exceptional products and unwavering dedication to quality. By focusing on research and development, pursuing innovation, and promoting sustainability, they have set new standards in the refractory industry. With an extensive portfolio of high-performance ramming mass, combined with their commitment to customer satisfaction, they are poised to continue driving growth and transforming the industrial landscape.

Get Top-Quality High Temperature Castable Refractory

Buy High Temperature Castable Refractory Boosts Industrial ProcessesCastable refractories have become a popular choice for industrial processes due to their excellent thermal properties. These materials are designed to withstand high temperatures and harsh conditions, making them ideal for use in furnaces, kilns, and other applications that involve extreme heat. Many industries rely on high temperature castables to optimize their manufacturing processes and extend the lifespan of their equipment. Therefore, leading manufacturers such as {remove brand name} offer a range of castable refractories to meet the diverse needs of their customers.One such product is high temperature castable refractory. This type of refractory is specially formulated to withstand temperatures above 3000°F. It is composed of a variety of raw materials, including high purity alumina, silicon carbide, and various binders. The combination of these components creates a refractory that is highly resistant to thermal shock, abrasion, and chemical attack. High temperature castables are commonly used in the steel, cement, glass, and petrochemical industries.In addition to its exceptional thermal properties, high temperature castable refractory has several advantages over traditional refractory materials. One such advantage is its ability to be cast into complex shapes. This allows manufacturers to create custom refractory linings that fit the exact specifications of their equipment. The castable nature of this refractory also makes it easy to install, reducing downtime and improving the efficiency of industrial processes.Another advantage of high temperature castables is their versatility. They can be used for a variety of applications, including furnace linings, burner blocks, and ladle linings. They are also suitable for use in a range of heating equipment, including kettles, crucibles, and incinerators. This makes them an ideal choice for industries that require high temperatures and need materials that can withstand harsh environments.{Remove brand name} is a leading manufacturer of high temperature castable refractory, offering a range of products that meet the diverse needs of their customers. Their castables are designed to provide exceptional performance in a range of applications, from steel and glassmaking to power generation and incineration. The company's castables are formulated with high purity raw materials and advanced binders, providing the optimal balance of strength and density.In addition to its high temperature castables, {remove brand name} offers a range of other refractory materials, including precast shapes, ceramic fiber products, and insulating materials. Their comprehensive product line makes them a one-stop-shop for industrial refractory needs, providing customers with the convenience of working with a single supplier.The company's dedication to quality is reflected in their ISO 9001 certification, which ensures that their castables and other refractory products meet the highest standards of quality. They also offer technical support and consultation services to help their customers identify the right refractory materials for their specific applications.In conclusion, high temperature castable refractory is an essential material for industries that require high-temperature resistance and durability in their industrial processes. {Remove brand name} is a leading provider of high-quality castable refractories, offering a comprehensive product line that meets the diverse needs of their customers. Their commitment to quality and customer service makes them a reliable partner for industries that rely on refractory materials to optimize their manufacturing processes.

Discover the Benefits of High-Quality Castable Cement for Your Project

High-Quality Castable Cement Taking the Industry by StormWhen it comes to the construction industry, one of the most important components is cement. Whether it's used for constructing a building or laying down a new road, the quality of the cement being used can play a huge role in the overall durability and longevity of the structure. Fortunately, in recent years, there has been a new product introduced to the market that is quickly taking the industry by storm: high-quality castable cement.As the name suggests, high-quality castable cement is a type of cement that is specifically designed for use in castable refractory applications. This makes it ideal for use in high-heat environments, such as blast furnaces, kilns, and incinerators. However, the benefits of castable cement don't just stop there. Here are just a few of the many reasons why this new product is quickly becoming a game-changer in the construction industry:Improved DurabilityOne of the biggest benefits of high-quality castable cement is that it has been shown to improve the overall durability of refractory structures. This is due to the fact that the cement offers superior bonding to the refractory aggregates, resulting in longer-lasting and stronger structures. Additionally, castable cement also has a high resistance to creep, shrinkage, and thermal stress, making it ideal for use in high-heat environments where other types of cement may fail.Higher PerformanceAnother key benefit of using high-quality castable cement is that it can help improve overall performance in a variety of applications. This is due to the fact that the cement has a high degree of purity and consistency, which allows it to perform consistently well over time. Additionally, castable cement has a low porosity, which means that it can withstand high temperatures without breaking down or deteriorating.Cost-EffectiveWhile many people assume that high-quality castable cement would cost more than traditional cement products, the reality is that castable cement can actually be quite cost-effective. This is due to the fact that it requires less maintenance and repairs over time, resulting in lower overall costs over the life of the structure. Additionally, the superior bonding and insulating properties of castable cement can help reduce energy costs, making it a smart investment for anyone looking to save money in the long run.Industry-Leading Providers of Castable CementWhen it comes to high-quality castable cement, one company in particular has emerged as an industry leader: [company name]. With years of experience in the industry, the company has been able to develop a top-notch castable cement product that has been widely praised for its superior performance and durability.In particular, [company name]'s castable cement has been shown to offer superior bonding and insulating properties, making it ideal for use in a variety of applications. Additionally, the company offers a wide range of castable cement products that are designed to meet the unique needs of each individual project, ensuring that customers can always find the right product for their needs.What's more, [company name] is committed to providing the highest level of customer service possible. The company's knowledgeable staff is always available to answer questions and provide guidance throughout the entire process, from selecting the right product to ongoing maintenance and support after the sale.ConclusionOverall, it's clear that high-quality castable cement is quickly becoming a must-have for anyone in the construction industry. With its superior durability, performance, and cost-effectiveness, it's no wonder that more and more professionals are turning to this innovative product for their refractory needs. And with [company name] leading the way with industry-leading castable cement products and unparalleled customer service, it's easy to see why the company is quickly becoming the go-to source for castable cement in the industry.

High-Quality Fire Bricks for Casting – Boost Furnace Efficiency

Castable Fire Brick: Providing Optimal Fire Protection Solutions[Company Introduction][Company Name], a leading provider of fire protection solutions, is proud to introduce its latest product, Castable Fire Brick. With our expertise in the industry and commitment to innovation, we have developed a superior firebrick that offers exceptional fire resistance, durability, and thermal insulation properties.[Company Name] has been at the forefront of the fire protection industry for over a decade. We specialize in manufacturing and supplying a wide range of high-quality fire-resistant materials, including fire bricks, refractory castables, and ceramic fiber products. Our products are designed to meet the stringent demands of various industries, such as steel, cement, glass, and petrochemical, ensuring the utmost safety and reliability in high-temperature environments.[Company Name]'s commitment to excellence has earned us a reputation as a trusted partner for fire protection solutions. We understand the importance of providing reliable and effective products that promote safety in industrial settings. Our team of experienced engineers and technicians work tirelessly to develop innovative fire-resistant materials, and our Castable Fire Brick is a testament to our dedication to advancing fire protection technology.[Castable Fire Brick]Designed to withstand extreme temperatures, [Company Name]'s Castable Fire Brick offers unparalleled fire resistance. It is manufactured using a combination of carefully selected raw materials, including high-quality alumina, silica, and other refractory aggregates. These materials are precisely mixed and bonded with a high-quality bonding agent, resulting in a dense and highly durable firebrick.One of the key advantages of our Castable Fire Brick is its excellent thermal insulation properties. It effectively retains and reflects heat, minimizing energy loss and reducing overall heating costs. This insulation capability makes it an ideal choice for industries that rely on high-temperature processes, as it ensures efficient heat management while providing superior protection against flames and thermal shock.In addition to its exceptional fire resistance and thermal insulation, our Castable Fire Brick also offers outstanding abrasion resistance and chemical stability. It can withstand harsh chemical environments and erosive conditions, making it suitable for a wide range of applications. Whether it is used for lining furnaces, kilns, incinerators, or other high-temperature equipment, the Castable Fire Brick provides long-lasting and reliable fire protection.Furthermore, our Castable Fire Brick is easy to install, enabling quick and hassle-free maintenance or repair in case of damage or wear. Its versatile nature allows for various installation methods, including casting, ramming, or gunning, ensuring suitability for different applications. This flexibility, combined with its excellent performance, makes our Castable Fire Brick a preferred choice for discerning customers seeking top-tier fire protection solutions.[Conclusion][Company Name]'s Castable Fire Brick sets a new standard in the field of fire protection materials. With its exceptional fire resistance, thermal insulation properties, and durability, it delivers optimal safety and performance in high-temperature environments. We are proud to offer this innovative product to industries worldwide, reaffirming our commitment to providing superior fire protection solutions.As leaders in the industry, [Company Name] remains dedicated to research and development, continuously striving to improve our products and meet the evolving needs of our customers. With our Castable Fire Brick, we aim to revolutionize fire protection and create a safer environment for industries globally. Trust [Company Name] for all your fire protection needs and experience the unparalleled quality and performance of our products.

Top-Quality High Liquidity Refractory Castable: Boost Your Project's Performance

Title: Pioneer Company Unveils High Liquidity Refractory Castable for Enhanced Industrial ApplicationsIntroduction (86 words):In a groundbreaking development, a renowned industry-leading company has introduced an innovative and powerful product to the market – High Liquidity Refractory Castable. Engineered with advanced technology and precision, this next-generation castable material is set to revolutionize industrial applications in various sectors. With its exceptional liquidity and superior performance characteristics, it promises to offer enhanced efficiency, durability, and cost-effectiveness solutions to industries across the globe.Paragraph 1 (115 words):High Liquidity Refractory Castable, developed by an industry pioneer, brings cutting-edge advancements to the field of refractory materials. Designed to withstand high temperatures and resist thermal shocks, this specialized castable constitutes a carefully formulated blend of high-quality raw materials. Its unique composition enables the castable to maintain its original fluidity for an extended period while exhibiting excellent flow and spreading properties. Due to its exceptional liquidity, it allows for easy installation and precise casting even in complex shapes, giving industries greater flexibility. Additionally, this castable offers exceptional mechanical strength, resistance to corrosion, and long-lasting thermal insulation, making it a highly sought-after solution for various demanding industrial applications.Paragraph 2 (110 words):The company responsible for this groundbreaking product has garnered significant global recognition for its expertise and commitment to innovation in the refractory industry. With over two decades of experience, they have become a trusted name, offering specialized solutions tailored to the diverse needs of different sectors. Their in-depth research and development efforts have led to the creation of High Liquidity Refractory Castable, further cementing their status as an industry leader. The company's team of highly skilled professionals and state-of-the-art manufacturing facilities ensure stringent quality control measures throughout the production process, resulting in a product that sets new standards for performance and reliability.Paragraph 3 (146 words):One of the distinguishing features of the High Liquidity Refractory Castable is its exceptional heat resistance capabilities, making it an ideal choice for high-temperature applications found in industries such as steel, ceramics, cement, and petrochemicals. This castable material offers outstanding thermal insulation, with low thermal conductivity that helps conserve energy and reduce operational costs. It also boasts impressive chemical resistance, ensuring durability even when exposed to aggressive environments or corrosive materials. Industries utilizing this castable can benefit from lower maintenance requirements, reduced downtime, and increased operational efficiency, ultimately contributing to long-term cost savings.Paragraph 4 (172 words):Moreover, High Liquidity Refractory Castable showcases remarkable adaptability, providing unparalleled design freedom to engineers and manufacturers. Its fluidity allows for precise casting into intricate shapes, resulting in reduced material wastage and labor costs. The castable's consistent setting time ensures quick and efficient installation, enabling industries to save valuable time during the production process. Its increased workability and ease of application make it an ideal solution for both repair and new construction projects. Whether for lining furnaces, kilns, incinerators, or any other high-temperature equipment, this castable stands out as a reliable, efficient, and versatile option.Conclusion (79 words):As the refractory industry continues to evolve, the introduction of High Liquidity Refractory Castable marks a significant milestone. With its advanced properties, impressive fluidity, and outstanding performance, this innovative product is poised to transform industrial applications across multiple sectors. Engineered by a trusted pioneer in the field, this castable material not only offers durability and enhanced thermal insulation but also provides industries with unparalleled design freedom and cost-effectiveness. As companies strive to optimize efficiency and productivity, this game-changing castable serves as a beacon of progress, paving the way for a new era in refractory engineering.

High-Quality Magnesite Refractory Bricks Meet Growing Demand in Steel Industry

Title: Evolving Magnesite Refractory Bricks Industry Emphasizes Quality and SustainabilityIntroduction:In recent times, the magnesite refractory bricks industry has been witnessing significant growth, driven by the increasing demand for high-quality refractory materials in various sectors. Magnesite refractory bricks, renowned for their exceptional heat resistance and durability, are widely utilized in industries like steel, cement, glass, non-ferrous metals, ceramics, etc., supporting critical processes that require elevated temperatures.Company Introduction:{Company Name} is a prominent player in the magnesite refractory bricks market, dedicated to producing top-notch products that meet the evolving needs of its customers. With years of industry experience, cutting-edge technology, and a strong focus on sustainability, {Company Name} has positioned itself as a trusted provider of magnesite refractory brick solutions worldwide.Evolution of the Magnesite Refractory Bricks Industry:The magnesite refractory bricks industry has experienced remarkable advancements in recent years. Formerly, the dominant types of refractories used were chrome bricks, but due to environmental concerns related to hexavalent chromium, there has been a gradual shift towards magnesite refractory bricks, known for their high refractoriness and excellent chemical properties.The versatility of magnesite refractory bricks has driven their adoption in various industries, replacing traditional refractory materials. Modern manufacturing processes have been optimized to enhance the physical and chemical properties of these bricks, making them increasingly resistant to thermal shocks and the corrosive effects of chemicals found in harsh industrial environments.Technological Innovations and Product Enhancements:{Company Name} recognizes the importance of technological advancements in staying ahead in the highly competitive market. The company consistently invests in research and development, aiming to improve the performance and durability of magnesite refractory bricks. High-precision manufacturing techniques, such as hot pressing, enable {Company Name} to produce bricks with more consistent and superior quality, ensuring excellent resistance to thermal stress and prolonged service life.Furthermore, {Company Name}'s commitment to sustainable practices is reflected in its innovative use of environmentally friendly raw materials and energy-efficient processes. By incorporating recycled materials within its manufacturing process, the company aims to reduce its carbon footprint and contribute to a greener future.Meeting Industry-Specific Demands:As diverse industries pose unique challenges, {Company Name} understands the importance of customizing magnesite refractory brick solutions accordingly. For instance, in the steel industry, refractory materials are exposed to extreme temperatures and harsh conditions during the smelting process. To address these challenges, {Company Name} has developed advanced magnesite refractory bricks with superior thermal stability, minimizing material degradation and extending the overall service life of the refractories.Moreover, {Company Name}'s research and development team works closely with customers, providing technical support and developing tailored solutions specific to their requirements. This customer-centric approach has fostered strong and lasting partnerships with clients across the globe.Commitment to Quality and Customer Satisfaction:{Company Name}'s commitment to quality and customer satisfaction has propelled its position in the market. The company adheres to strict quality control procedures, guaranteeing that each magnesite refractory brick meets stringent international standards. Moreover, providing exceptional after-sales service and technical assistance ensures that customers maximize the value and performance of {Company Name}'s refractory solutions.Conclusion:The magnesite refractory bricks industry is witnessing transformational changes as sustainability, high performance, and customized solutions become paramount. {Company Name} is at the forefront of this evolution, delivering top-quality magnesite refractory bricks while embracing innovation and sustainable practices. With its unwavering commitment to customer satisfaction and its focus on technological advancements, {Company Name} is well-positioned to meet the ever-increasing demand for superior refractory materials in the global market.

Discover the Benefits of Acid Resistant Refractory Castable for Your Needs

[Your Name][Date]Acid Resistant Refractory Castable: Revolutionizing High-Temperature Applications[City, State] - Acid Resistant Refractory Castable, an innovative product developed by [Company Name], is set to revolutionize high-temperature applications across a range of industries. With its exceptional durability and resistance to acidic environments, this castable material is a game-changer for businesses seeking reliable and cost-effective solutions.[Company Name] has been at the forefront of refractory materials for [number of years] years, specializing in the development and production of advanced ceramics and composite materials. With a dedicated team of researchers and engineers, the company has consistently pushed the boundaries of what is achievable in high-temperature applications.Acid Resistant Refractory Castable is the result of extensive research and development efforts by [Company Name]. This cutting-edge product offers superior resistance to acids, alkalis, and other corrosive substances found in various industrial processes. By withstanding the harshest conditions, this castable material significantly extends the service life of refractory linings, thereby reducing downtime and maintenance costs for businesses.One of the key advantages of Acid Resistant Refractory Castable is its exceptional chemical stability. The unique composition of the castable material allows it to withstand continuous exposure to strong acids, such as sulfuric acid and hydrochloric acid, without deteriorating or losing its properties. This not only enhances the overall performance of the refractory lining but also ensures the safety of personnel working in corrosive environments.Furthermore, the castable material exhibits excellent thermal shock resistance, enabling it to withstand rapid temperature changes without cracking or spalling. It can endure temperatures of up to [temperature range], making it suitable for a wide range of applications, including furnaces, kilns, reactors, and various chemical processing equipment.The installation process of Acid Resistant Refractory Castable is efficient and convenient, thanks to its excellent workability and flowability. This allows for precise and uniform casting, ensuring a seamless refractory lining that maximizes performance and reduces heat loss. Moreover, the material demonstrates excellent adhesion to various substrates, including bricks, steel, and concrete, providing a reliable and long-lasting solution for businesses.To meet the diverse requirements of different industries, [Company Name] offers customizable options for Acid Resistant Refractory Castable. The product can be tailored to specific project needs, including different chemical resistance levels, particle size distributions, and setting times. This flexibility ensures that customers receive a product that precisely matches their unique application requirements.Acid Resistant Refractory Castable has garnered positive feedback from numerous industries, including the petrochemical, metallurgical, and power generation sectors. "We have witnessed a noticeable improvement in the durability of our refractory linings after switching to Acid Resistant Refractory Castable," said [Company representative]. "This has led to significant cost savings and increased overall operational efficiency."[Company Name] continues to invest in cutting-edge research and development, striving to improve and expand their product line to meet evolving industry demands. In addition to Acid Resistant Refractory Castable, the company offers a wide range of refractory materials and solutions, including monolithic castables, ceramic fiber products, and high-temperature insulation materials.With Acid Resistant Refractory Castable, [Company Name] is leading the charge in providing reliable and cost-effective solutions for high-temperature applications. This revolutionary product is set to reshape several industries, enabling businesses to operate in corrosive environments with confidence, durability, and enhanced efficiency.About [Company Name]:[Company Name] is a leading provider of advanced refractory materials and solutions. With a strong focus on research and development, the company offers a wide range of high-quality products that cater to diverse industry needs. [Company Name]'s commitment to innovation, quality, and customer satisfaction has positioned it as a trusted partner for businesses worldwide.For media inquiries, please contact:[Company Contact Information]

High-Quality Mullite Bricks Now Available for Sale: Discover the Latest Advancements in Zircon Technology

Zircon Mullite Brick revolutionizes the refractory industry with its exceptional performance, durability, and resistance to high temperatures. The product has been widely used in various industries such as steel, ceramics, petrochemicals, and non-ferrous metals, where heat and chemical resistance are crucial.Zircon Mullite Brick is a high-quality refractory product made of high-purity zirconium oxide, aluminum oxide, and mullite. The combination of these materials offers excellent heat resistance, thermal shock resistance, and high strength. Moreover, the brick is not vulnerable to the corrosive effects of acids and alkalis, which makes it highly suitable for industrial applications.The manufacturing process of the product involves complex techniques and the use of advanced equipment. The raw materials undergo a process of grinding, mixing, molding, firing, and cutting, which ensures uniformity in dimension, density, and mechanical properties. The high-quality manufacturing process guarantees consistent performance and durability of the product, making it an ideal choice for customers.The company behind the production of Zircon Mullite Brick is a leading refractory material manufacturer in China. It has a long history of producing high-quality refractory products that meet the diverse needs of customers. The company has invested in research and development to improve its products and manufacturing processes continually. It has also been using technology to improve efficiency and reduce the environmental impact of its production.The company has strict quality control measures in place to ensure that its products meet international standards. It has obtained ISO 9001:2015, ISO 14001:2015, and OHSAS 18001:2007 certifications, which attest to its commitment to quality, safety, and environmental protection. The company also has a dedicated technical team that offers technical advice and assistance to customers, ensuring that they get optimum performance from the products.In recent years, the company has expanded its operations beyond China and has established a global presence. It has set up offices and warehouses in various countries, enabling it to serve customers around the world. The company has also adopted international marketing strategies to increase its visibility and reach out to more customers. With its high-quality products, competitive pricing, and excellent customer service, the company has become a preferred supplier of refractory materials to many industries.Zircon Mullite Brick is one of the company's flagship products, and it has received positive feedback from customers. The brick's exceptional performance, durability, and resistance to high temperatures have made it a popular choice in industries such as steel and ceramics. The product offers excellent value for money and is comparable to other top-tier refractory products in the market.In conclusion, Zircon Mullite Brick is a high-quality refractory product that has revolutionized the industry with its exceptional performance, durability, and resistance to high temperatures. The product is made by a leading refractory material manufacturer in China, which has a long history of producing high-quality refractory products. The company has strict quality control measures in place to ensure that its products meet international standards and has a dedicated technical team that offers technical advice and assistance to customers. With its global presence, competitive pricing, and excellent customer service, the company has become a preferred supplier of refractory materials to many industries.

Strong and Durable Acid Resistant Castable for Industrial Use

Acid Resistant Castable, the Leading Solution for Demanding Industrial EnvironmentsIndustries that handle strong acids and gas emissions require the most innovative materials to withstand the harsh and corrosive environment. For more than two decades, Acid Resistant Castable (ARC) has been at the forefront of manufacturing such solutions. ARC has grown to become an international reference in the production of special concrete, serving a wide range of industries, including petrochemicals, electricity generation, and the pharmaceutical industry.ARC is renowned for its excellent chemical resistance, mechanical properties, and durability, making it ideal for hostile environments. Its key features include:Resistance to high temperatures: Acid Resistant Castable can withstand extreme temperature fluctuations from -150°C to +1800°C. It is designed to maintain chemical stability and mechanical strength while exposed to harsh conditions, ensuring top performance.Exceptional chemical resistance: ARC can resist attacks from a wide range of acids, including sulfuric acid, hydrochloric acid, nitric acid, and other strong acids. This resistance makes it stand out from regular concrete, which is easily corroded by such substances.Superb mechanical strength: Acid Resistant Castable's unique strength properties enable it to hold up against external forces, such as compression, bending, and impact.Ease of installation: One of the main benefits of ARC is its ease of installation. It is easy to mix and install, with no need for vibration, which reduces installation time and costs.ARC ApplicationsThe demands of modern industry require reliable, efficient, and long-term solutions that meet the most stringent safety and environmental requirements. ARC is an essential ingredient in numerous industrial applications, including:Chimneys and furnacesThe chemical industriesIncinerators, kilns, and reactorsPower plants and thermal energy productionPetrochemicals and fertilizer manufacturingWaste management facilitiesPharmaceuticals and healthcareMolten metal handlingFor example, in the petrochemical industry, ARC is widely used in acid storage reservoirs, reaction vessels, distillation columns, and other installations that require high-temperature and strong acid-resistant materials.The production of Acid Resistant CastableStarting with an advanced proprietary mixture of various minerals, together with high-purity chemical components, the production of ARC uses a unique manufacturing process. The different minerals undergo an intensive grinding process to obtain a precise particle size distribution to guarantee maximum strength.ARC production process is a precise and strictly controlled system with a high level of quality assurance. The production line includes modern facilities that can control temperatures up to 2500°C, ensuring the complete, homogenous calcination of the raw materials. The end result is a high-density, corrosion-resistant material that meets the most rigorous safety standards.Benefits and environmental protectionARC offers a vast array of benefits, including the reduced environmental impact of industrial processes as it aids in reducing the emission of toxic and hazardous gases. The durability and chemical resistance of ARC ensure long-term usage, reducing the amount and frequency of material replacements. This significantly reduces the amount of waste materials in landfill sites. At the same time, manufacturing processes support the principles of 'green chemistry' that emphasizes minimal environmental impact during the manufacturing process.In conclusionIn the modern era, industrial processes must balance operational efficiency with environmental responsibility. Chemical resistance, durability, and strength are fundamental features that industry demands from products used in aggressive industrial environments. ARC meets all such demands and requirements. ARC's qualities make it a versatile solution suitable for use across several industries. Its benefits also include being environmentally friendly, and by reducing waste and toxic emissions published into the environment, ARC proves itself to be a sustainable solution, while its ease of installation and long-term usage allows for cost-effective budget planning. With over two decades of serving the world’s industries, Arc has become a synonym for quality, reliability, and trust, and personal commitment to each project.

Find High-Quality Insulating Castable Refractory for Purchase

Title: [Company Name] Releases Innovative Insulating Castable Refractory to Enhance Industrial Heat ManagementIntroduction (100 words):[Company Name], a leading provider of advanced refractory solutions, has recently introduced its new line of high-performance insulating castable refractories. Combining cutting-edge technology with years of industry expertise, these innovative refractories aim to revolutionize industrial heat management. With their exceptional thermal insulation properties, durability, and ease of use, [Company Name]'s insulating castable refractories are poised to significantly enhance energy efficiency and cost-effectiveness across various industrial sectors. This news article will delve into the unique features and benefits of these refractories while providing a glimpse into [Company Name]'s dedication to delivering top-quality solutions to its customers.Section 1: Overview of Insulating Castable Refractories (200 words)Insulating castable refractories have emerged as a game-changer in the industrial sector, providing an effective solution to manage heat efficiently and safely. These refractories are specially designed to minimize heat loss, maintain temperature uniformity, and increase energy efficiency in high-temperature applications such as furnaces, kilns, boilers, and incinerators.[Company Name]'s new line of insulating castable refractories takes this concept to the next level with advanced materials and precise engineering. Engineered with a combination of lightweight aggregates, high-purity binders, and insulating fibers, these refractories offer superior insulation properties while maintaining excellent mechanical strength. This unique composition empowers industries to optimize their heat management processes, resulting in reduced energy consumption, improved product quality, and enhanced operational stability.Section 2: Key Features and Benefits (250 words)[Company Name]'s insulating castable refractories offer several noteworthy features and benefits that set them apart from traditional refractory materials. Firstly, their low thermal conductivity minimizes heat loss, ensuring efficient heat retention within the system. This leads to reduced fuel consumption, lower operating costs, and a significant decrease in carbon emissions, aligning with global sustainability initiatives.Additionally, the high strength and abrasion resistance of these refractories make them ideal for various industrial applications. Their exceptional durability and resistance to mechanical shocks prevent cracks and thermal spalling, leading to extended refractory lining lifespans. This not only reduces downtime and maintenance costs but also improves overall productivity.Moreover, [Company Name]'s insulating castable refractories can be easily shaped and installed, thanks to their excellent workability and flowability. Their low water demand and superior adhesion properties ensure smooth application, allowing for custom designs and optimized thermal insulation. This flexibility caters to diverse customer requirements, making these refractories suitable for a wide range of industries, including steel, cement, petrochemicals, and power generation.Section 3: [Company Name]'s Commitment to Excellence (200 words)[Company Name] has gained a stellar reputation in the refractory industry for its unwavering commitment to delivering innovative and high-quality solutions. With decades of experience, the company has continuously invested in research and development, pushing the boundaries of refractory technology.Their insulating castable refractories have undergone rigorous testing and quality control measures to ensure optimal performance and customer satisfaction. [Company Name] maintains strict adherence to international standards and certifications, reflecting their dedication to excellence and safety.Furthermore, the company's technical support team offers comprehensive guidance and after-sales services to assist customers in selecting the right products and optimizing their usage. By understanding individual application requirements, [Company Name] helps industries implement the most effective heat management solutions, thereby improving their operational efficiency and profitability.Conclusion (50 words):[Company Name]'s breakthrough insulating castable refractories mark a significant advancement in industrial heat management. By introducing this innovative product line, the company reaffirms its commitment to excellence and sustainability while providing industries with superior thermal insulation solutions. With [Company Name] at the forefront of refractory technology, the future of efficient heat management looks promising.